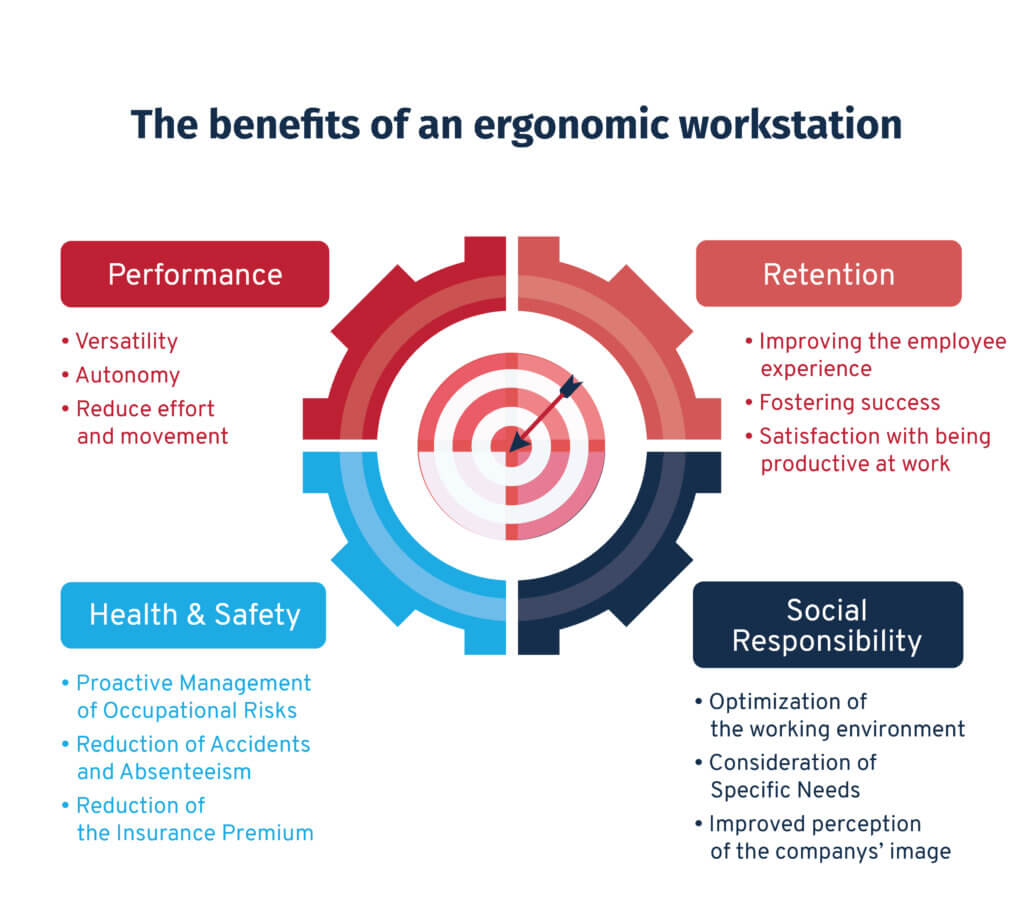

In a context where manufacturing companies are juggling production capacity issues, labor shortages, training, and a high turnover rate, the design of work environments can play a key role in facilitating the retention of your employees. This is an interesting solution to implement in your organization that improves the workspace of your employees. Ergonomic workstations improve productivity and team performance in companies and reduce workplace accidents and absenteeism.

ALSO TO BE READ: The Best Tools to Increase Your Manufacturing Capacity

Better Design of Work Environments, a Strategy that Pays Off

In the current context of labour shortage, quality requirements and strong competitiveness force manufacturing companies to look for ways to increase productivity and work safety. In addition, some companies want to respond to sales growth and are forced to redefine their internal processes. Many positions require physically demanding, even repetitive work and must remain attractive to employees in order to avoid a high turnover rate in the teams.

Heavy manual handling or repetitive tasks can also lead to musculoskeletal injuries or other work-related illnesses: they are even one of the most common causes of worker absence and generate significant financial and social burdens that employers prefer to avoid. For example, absenteeism and work-related accidents have a direct impact on insurance costs. Physical constraints, which are often significant, can be corrected by implementing ergonomic measures. Several studies have shown that it is necessary to improve the conditions of the work itself in order to ensure the retention of workers and to respond to the labour shortage.

As shown in the diagram above, integrating ergonomics into the workstation allows for very significant production gains, in addition to reducing effort, eliminating the risk of injury at the source, reducing unnecessary movements and improving cycle time. With a simple and adapted technical layout (example: conveyor, lifting table, visual management), gains are quickly apparent:

- Increased and stable productivity

- Reduced travel time

- Reduced effort and fatigue for the person

- Less waste and scrap

A company that focuses on ergonomics can save up to 75% of travel time with ergonomic workstations located in the right places in the production area, in addition to the benefits related to employee comfort and safety.

Studies in American companies have already shown that $1 invested in ergonomics has a return on investment (ROI) of $2 to $6.

A workstation designed to facilitate learning time

Analysis of postures, points

With the right layout and the right tools, placed in the right place, an operator will develop an expertise and a rate of return based on his strengths. As a result, having become comfortable in his current position, he will perform better and better and will progress in the company with increasing motivation. By implementing strategies to make an operator’s workstation more efficient, he will perform his tasks more easily; his risk of errors and injuries will be greatly reduced, and his comfort maximized. These types of measures help minimize the amount of training required for new employees. Precise work instructions and pictograms installed at the workstation can also guide the operator and the various employees in rotation on the same shift.

Some simple rules to consider

- Identify every opportunity for “health-performance” gains in your operations by removing low value-added activities:

- Optimize your production and traffic flows.

- Reduce the causes of non-quality.

- Simplify tasks.

- Arrange the working heights and gripping areas according to the guidelines for a better postural comfort, dexterity and quality of work done:

- Adapt workstations according to the activity in order to promote comfortable postures for the employee.

- Keep the most frequently used items within the worker’s reach (primary zone). Less frequently used items can be placed further away (secondary zone). Objects used very occasionally and of a reasonable weight can be placed a little farther away, requiring the worker to move his or her upper body forward to reach it (tertiary zone). This arrangement reduces the need for workers to stretch excessively and repeatedly.

- Promote visual management at workstations to be efficient and gain autonomy while limiting the risk of errors:

- Standardize workstations (select / locate / scintillate / standardize / follow).

- Integrate the key tools of continuous improvement to develop team autonomy.

Conclusion

In this article, we have seen that improving workplaces is a win-win for employees and the company. The corporate culture must position employees as stakeholders in the design of work environments. Long before optimizing production, it is necessary to communicate all the benefits that this will bring to them daily: comfort, satisfaction, reduced risk of injury, and easier maneuvers. Happy and efficient employees will find satisfaction in their daily work, which in turn will improve the company’s performance: the best of both worlds!

We invite you to contact our Merkur experts who will be happy to assist you in your project.

ABOUT US

MERKUR is a firm of experts in manufacturing performance and innovation and has been doing so for over 25 years. From strategy to execution, its sole objective is to make Quebec’s manufacturing companies more efficient by offering innovative solutions in product development, operational excellence, manufacturing engineering, automation and smart factory. Merkur is proud to contribute to innovation and productivity in Quebec!

KHROME PRODUIT TRANSPORT is a manufacturing integrator located in Drummondville specialized in the design and manufacturing of train car interiors and exteriors. Its strength comes from its great engineering capacity and its manufacturing agility. Among its customer portfolio, there are major manufacturers such as Alstom, Bombardier Transportation and Kawasaki Rail Car.

SYNKRO is a software developed by Merkur and designed specifically for high-performance manufacturers. It collects, classifies, and distributes the right data to the right people at the right time. SYNKRO gives you a real vision of your operations. SYNKRO is the software solution that finally connects your floor and your offices!