Development of Bus Handling Equipment

- Client

- Confidential

- Sector

- Transportation

- Expertise

- Industrial Project Management

- Industrial Automation and Robotics

- Numerical Simulation and Physical Testing

- Manufacturing Simulation

CONTEXT

CHALLENGES

ASSIGNMENT

Our customer wanted to work with Merkur. They were looking for a partner with the technical skills in mechanical, electrical and automation engineering.

They also needed Merkur’s ability to take the lead in rallying stakeholders and ensuring the success of the project.

RESULTS

20%

increase in cross-boarding capacity and simplified operation

OBJECTIVE AND ACTIONS

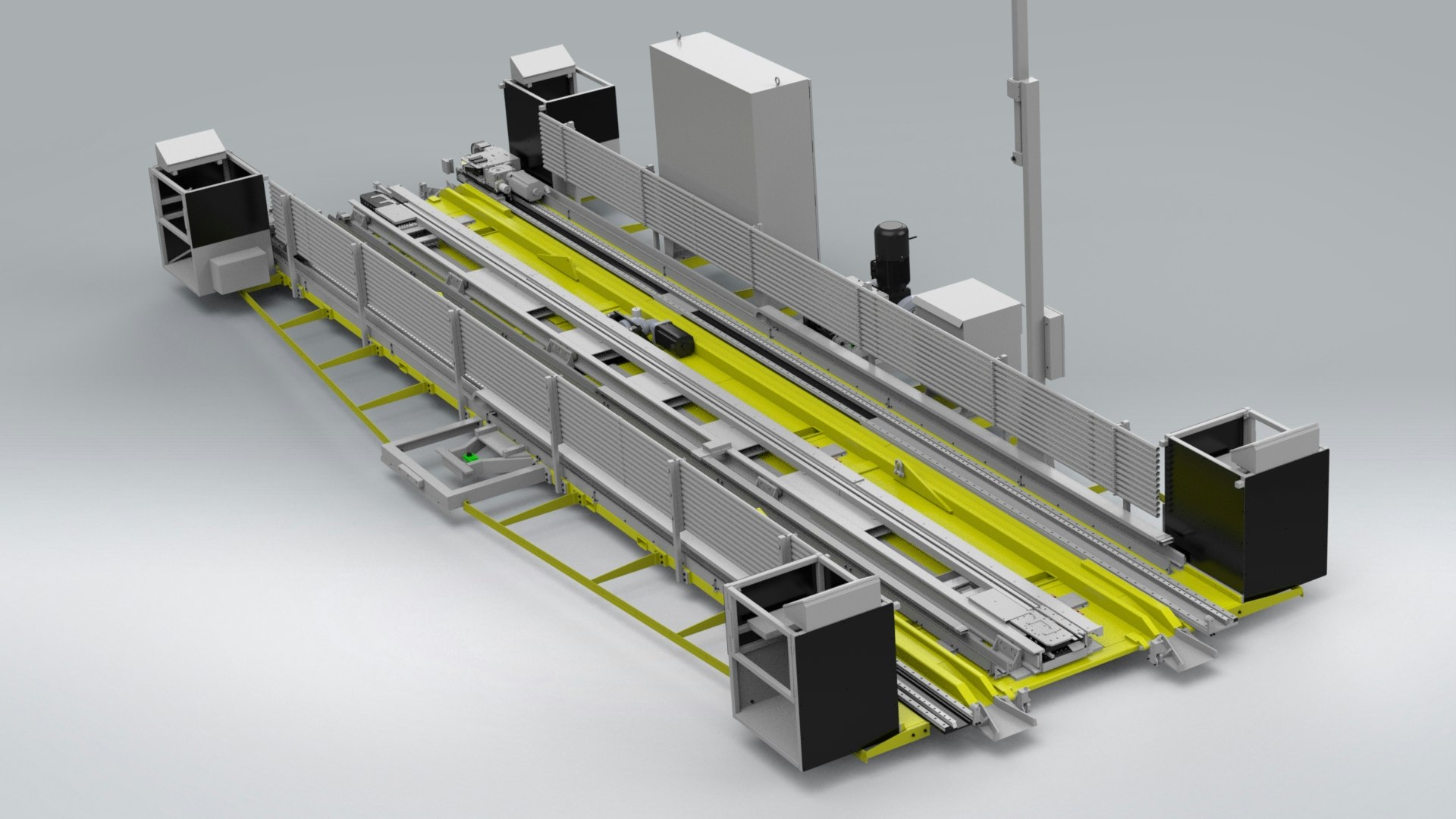

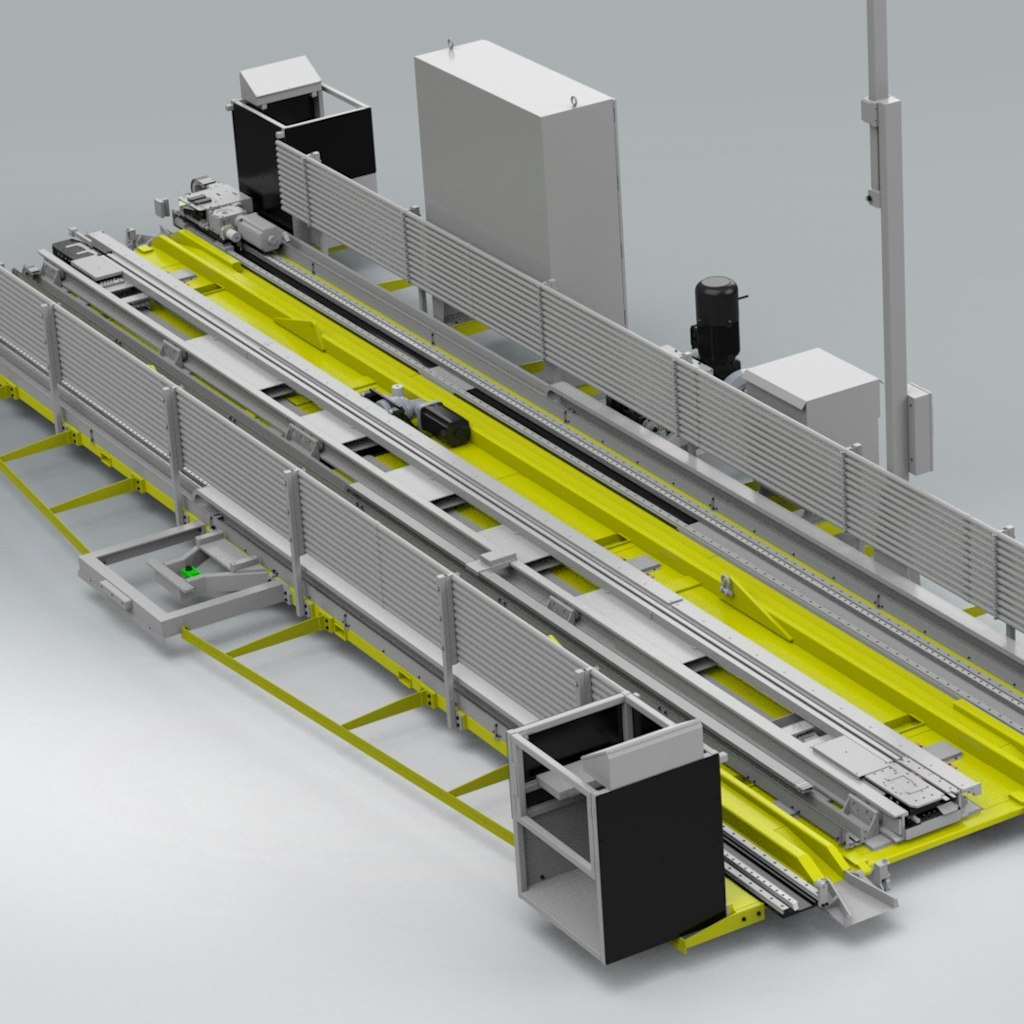

Replace existing obsolete equipment

Replace existing obsolete equipment

Develop and design all systems for new-generation ferry equipment.

- Make operations more reliable

- Reduce maintenance costs and facilitate servicing

- Make equipment operation intuitive

- Increase cross-docking capacity

TOOLS AND TECHNIQUES

Operations Simulation - FlexSim®

Automation Strategy Methodology

FEA – material resistance

Design software: SolidWorks®

This project demonstrates our commitment at Merkur to offering tailor-made solutions to our customers. Our collaborative approach enabled smooth communication and total adaptation to their preferences, guaranteeing optimal project success!

Louis Labonté, ing. PMP

Manufacturing Project Director

Merkur

DISCOVER OUR PROJECTS

Integration of an Electronic Module for Motorized Watercraft

Electrification

Merkur worked with one of its customers, a manufacturer of motorized watercraft and recreational vehicles, to modernize one of its pieces of equipment.

Accelerating the Production Launch of a Oneka Desalination Buoy

Marine

Oneka Technologies is a startup dedicated to transforming the oceans into a sustainable and affordable source of fresh water. Oneka sought to integrate several supply chain and product development experts into its team to help plan manufacturing through its supplier network and bring the buoy into production.

Design and simulation for the passenger seats of the Long Island Rail Road In New-York

Transportation

Developed for daily commuters on New York’s suburban rail lines, the M9 seats were manufactured by our client, Khrome PT, on behalf of Kawasaki. The twofold objective was to meet strict transportation safety standards while also complying with the railcar manufacturer’s technical specifications—all within the established budget.