The Essential Benefits of Robotic Simulation for your Project

Before starting a new project or implementing a new robot, have you considered robotic simulation? It helps you anticipate challenges, optimize processes, and guarantee overall project success, while minimizing risks and associated costs. How can we do this? Let's take a look at robotic simulation and its many benefits, to help make your project a success!

LEARN MORE: Industrial Automation and Robotics

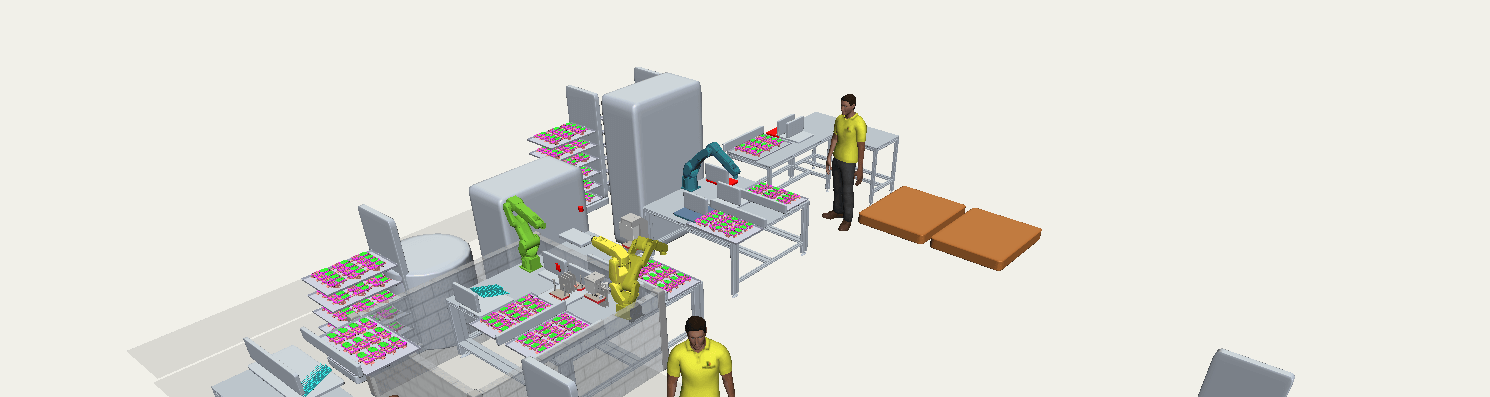

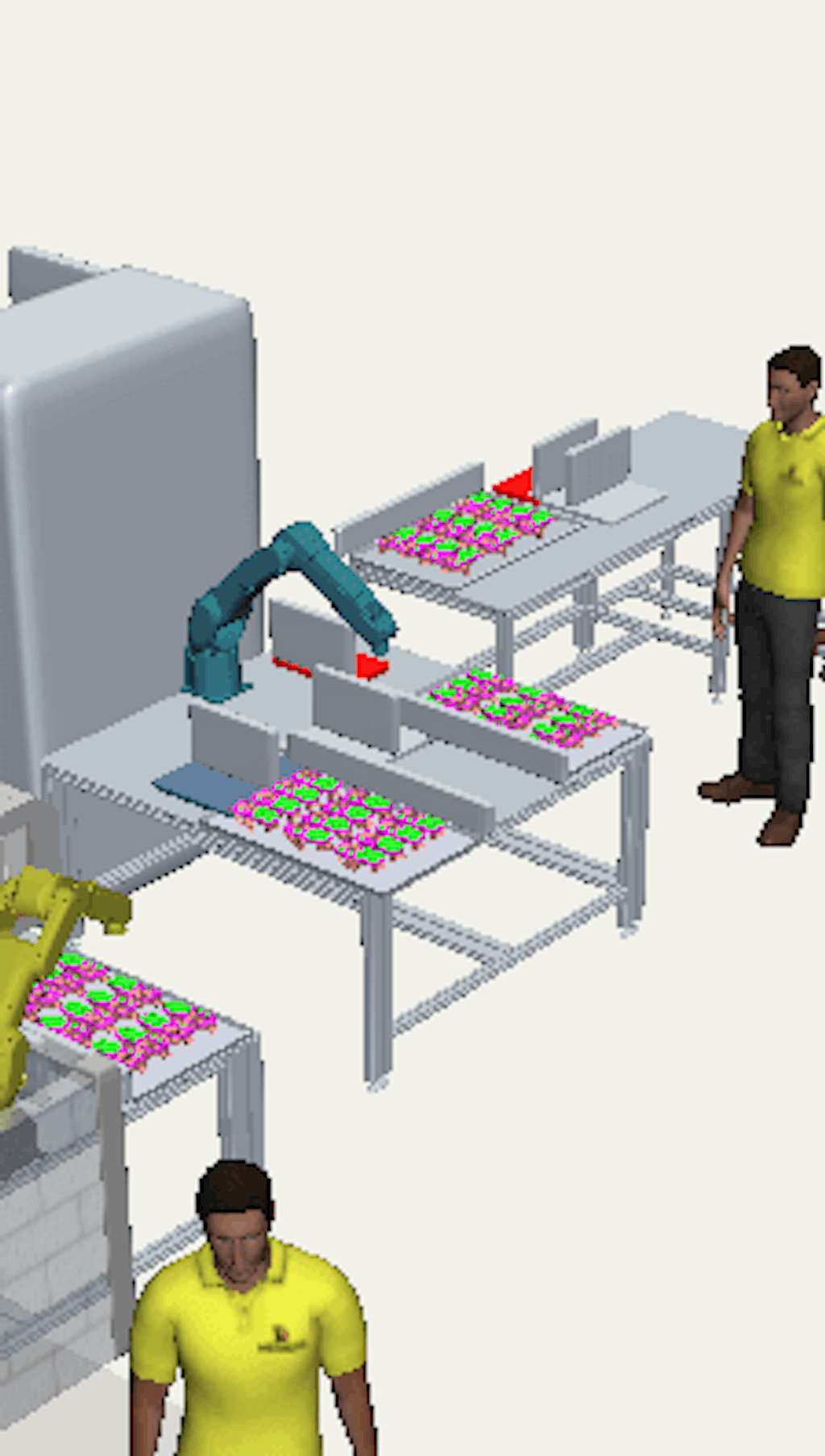

Robotic simulation consists of creating a realistic digital model of a robotic system, running it in a virtual environment, and evaluating its performance before real-world implementation. Imagine a powerful tool that allows you to visualize, in a realistic three-dimensional way, how your future robot will integrate into your production environment. This enables you to assess whether your performance objectives are achievable, whether the robot can navigate efficiently within the available space, and whether cycle times are viable. Robotic simulation makes it possible to anticipate issues, optimize parameters, and ultimately ensure the success of your project.

Here is an example of a simulation previously carried out by Merkur

Before starting any robotic simulation project, let's explain the key benefits that will help you avoid common pitfalls and maximize the value for your project.

The 4 Main Benefits of Robotic Simulation

- Realistic and convincing projection: convincing stakeholders of the relevance of your project becomes easier when you can show them a realistic simulation of how it works.

- Significant time savings: for robot programmers, each simulation step translates directly into time saved during actual programming.

- Cost savings: to illustrate this advantage of opting for robotic simulation, let me tell you about a customer case. He specializes in electronic components and was able to save precious time by validating his project using robotic simulation, thus avoiding unnecessary costs.

- Safety and training: simulation provides a safe environment for training novices in the use of robots, reducing the risk of accidents and speeding up the training process.

Why is Robotic Simulation Crucial?

If you neglect simulation, you could end up with a robot that's ill-suited to your needs, leading to major financial losses and project delays. Programming directly on the robot without prior validation can be costly and risky.

How do you Run an Effective Robotics Simulation?

The steps are crucial: make sure you test the layout in 3D, avoid collisions, check cycle times, and much more. Stay tuned for a complete guide to running an effective simulation in a future article! Finally, we leave you with a few practical tips before diving into robotic simulation:

- Make sure your CAD files are in the right format.

- Polish your layout and make sure everything is correctly dimensioned.

- Keep a precise record of the origin of your parts for smooth simulation.

How Merkur Supports You in Automation and Robotics

We're with you every step of the way, from initial design to commissioning of robotic equipment. We offer a full range of automation and robotics services. Our automation and robotics experts are available to provide the advice and assistance you need to bring your project to fruition.

Whether you need manufacturing automation assistance, industrial programming outsourcing or commissioning support, our experienced team is here to guide you. We specialize in machine optimization, robotic cell simulation, and the implementation of customized robotic solutions to meet your specific industrial automation needs.

We also offer expertise in automation strategy, automation and robotization support, and systems integration. Whether you're looking to implement a machine vision solution or deploy robotic equipment, our integration service is here to help you achieve your goals.

With Merkur, you have a partner you can trust to bring your industrial automation project to fruition. Don't leave your project to chance: contact us today to get started on the road to automation success.