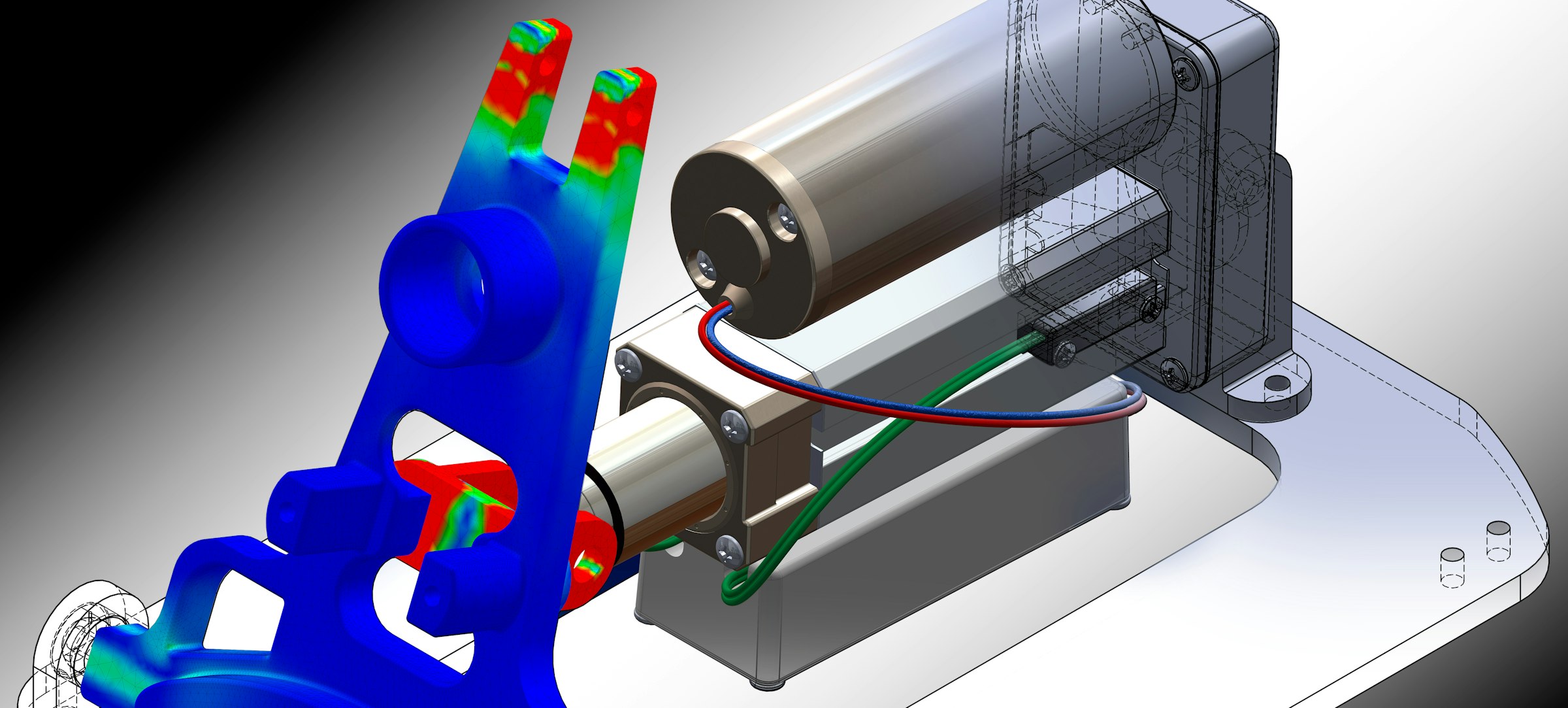

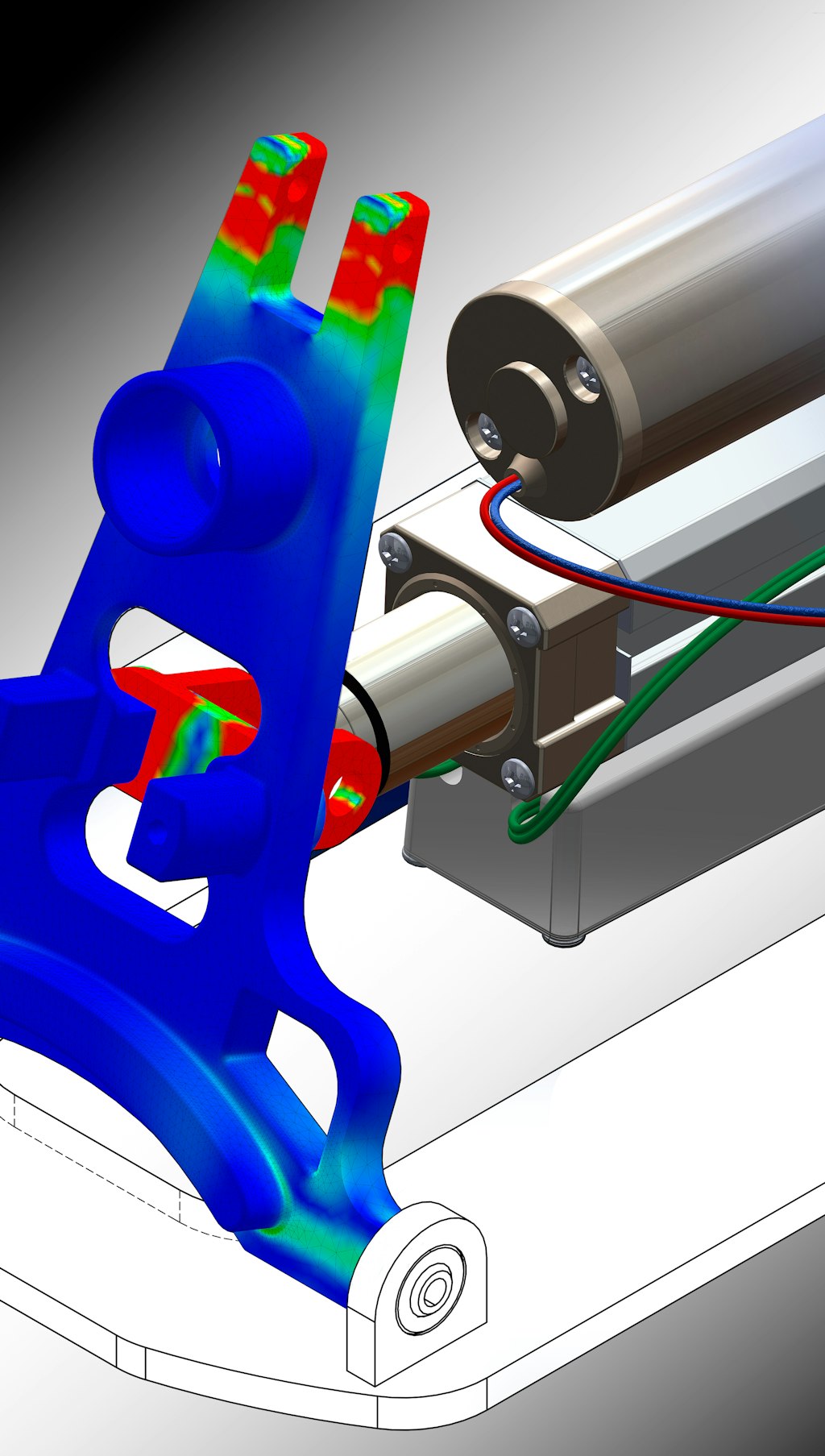

Digital simulation and physical testing

Anticipate risks and validate your designs earlier by combining the power of digital simulation with instrumented physical testing. Speed up technical decisions, optimize product performance, and secure a smooth transition to production.

OUR EXPERTISE

From simulation to field testing: master your products’ behavior

From simulation to field testing: master your products’ behavior

We support your projects from design through validation by combining advanced digital simulation with targeted physical testing. This integrated approach helps you anticipate behavior, reduce costly iterations, and secure the transition to production.

Through modeling (structural loads, thermal behavior, vibrations, fluid flow), generative design, and artificial intelligence, we explore optimized solutions and automate certain analyses. Finally, our lab tests and real-world trials confirm performance and strengthen confidence in your technical decisions.

- Anticipate the mechanical, thermal, and dynamic behavior of your products

- Identify stresses, deformations, and fatigue points early in the design phase

- Improve geometries using generative design and AI

- Confirm concepts through targeted physical testing

- Compare simulations with real data to validate your choices

- Reduce iterations and speed up delivery

- Rely on robust, standards-based, traceable data

Tools

SolidWorks Simulation, ANSYS, Abaqus, Fusion360, Simulia

Linear, non-linear, modal, and vibration analysis

Matlab, LabVIEW, Excel, Python

Mechanical, fatigue, thermal, and vibration testing

Instrumentated tests bench

Do your projects require more than simple calculations? With our integrated approach, combine advanced digital simulation with targeted physical testing to secure your decisions and shorten time to market.

Anticipate behavior before production

Using digital and generative simulation, we identify critical areas early, optimize your geometries, and reduce the need for physical tests.

Validate your designs with our specialists

Our test protocols confirm performance and safety, validate assumptions, and adjust your designs based on real-world results.

Bring together intelligence, data, and expertise

Accelerate development and secure pre-production decisions by combining modeling, AI, and physical testing.

PROJECTS

Numerical Simulation for the Company Pro Pac Industries

Manufacturing

Pro Pac Industries, a major company in the forestry domain, wanted to carry out a major upgrade of its product line. To meet their needs and obtain assistance in the design and improvement of various delimber head models, they called on Merkur’s numerical simulation experts.

Design and simulation for the passenger seats of the Long Island Rail Road In New-York

Transportation

Developed for daily commuters on New York’s suburban rail lines, the M9 seats were manufactured by our client, Khrome PT, on behalf of Kawasaki. The twofold objective was to meet strict transportation safety standards while also complying with the railcar manufacturer’s technical specifications—all within the established budget.

ARTICLES

Generative Design: Merging Human Intuition and Artificial Intelligence

In product development, some innovations take time to catch on—until they become simple enough to transform everyday practices. That’s exactly what’s happening with generative design, an AI-powered approach that helps design faster, lighter, and smarter by focusing solely on what matters.

Take the Opportunity to Innovate

The word innovation is on everyone’s lips: the importance of innovating, of finding innovative solutions. Yes! But how? How can we do this, when day-to-day business often takes precedence over creative and strategic thinking?

Knowing your Market and your Customers: The Key to Successful Product Development!

Do you see opportunities for innovation and improvement that could benefit your company? Do you have a project in mind that you’d like to present? Make the most of the summer to get ready!