Generative Design: Merging Human Intuition and Artificial Intelligence

What if a designer’s role was no longer to draw a part, but to set the right conditions?

In product development, some innovations take time to catch on—until they become simple enough to transform everyday practices. That’s exactly what’s happening with generative design, an AI-powered approach that helps design faster, lighter, and smarter by focusing solely on what matters.

At Merkur, we’ve been exploring this approach for quite some time—not because it’s trendy, but because it works. And now more than ever, Quebec SMEs can consider integrating it into their processes, as long as it’s applied at the right time, to the right project, and with the right approach.

LEARN MORE: Numerical Simulation and Physical Testing

Design Less, Design Better

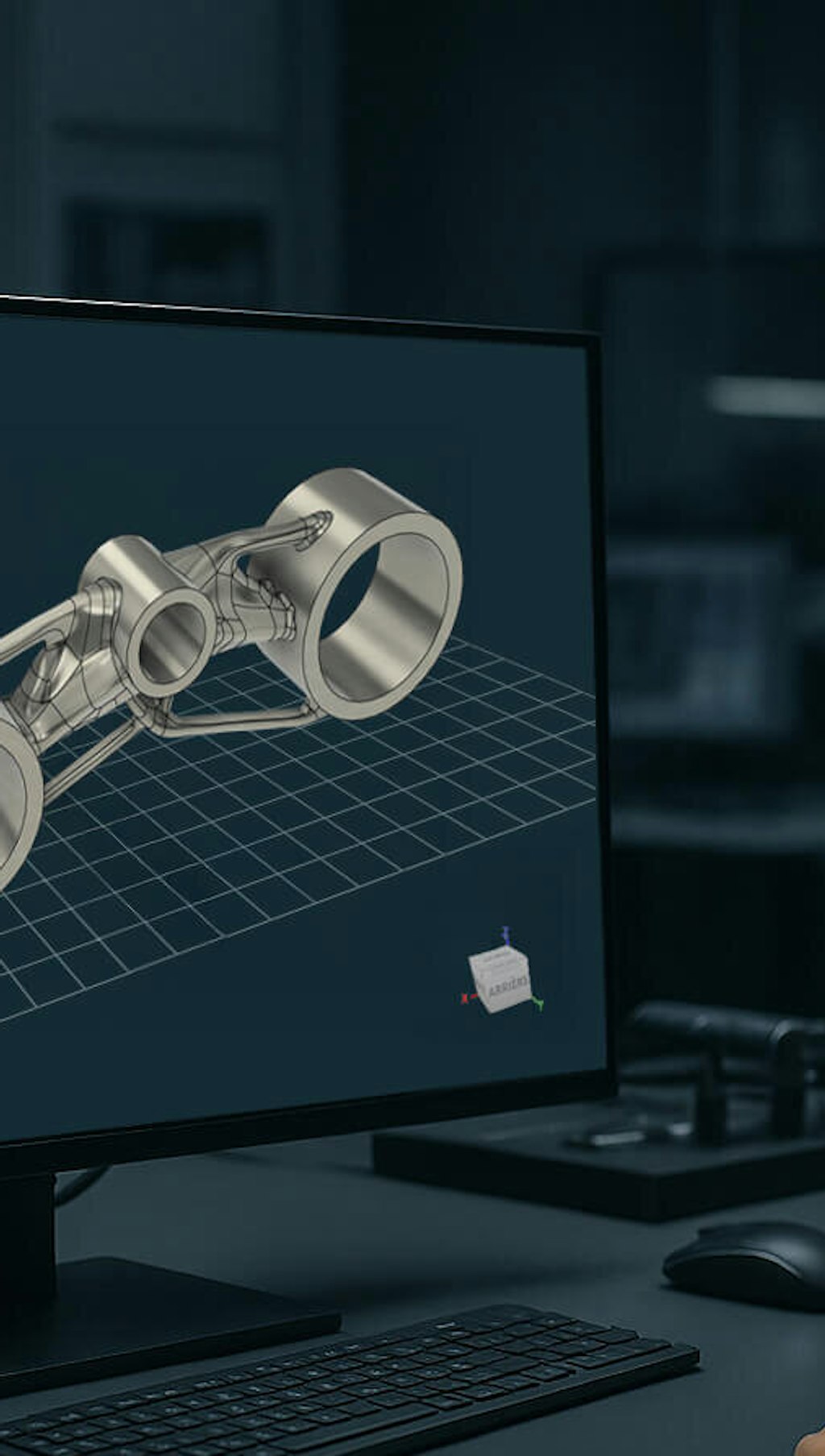

Generative design transforms the way we approach engineering. It’s no longer about drawing a part from a fixed idea, but about defining a set of parameters—such as attachment points or mechanical loads—and letting artificial intelligence explore all possible solutions.

The algorithm evaluates, refines, eliminates what’s unnecessary, and proposes a final form that meets all the defined constraints. This approach enables the creation of lighter, optimized parts—often featuring organic geometries—designed to maximize performance while minimizing material use.

That said, technology doesn’t replace the designer or engineer—it gives them new tools. It’s up to them to set the right boundaries, interpret the AI-generated proposals, and make final decisions. The human remains at the core of the process.

From Lab to Workshop: Generative Design Becomes Accessible

Once reserved for large corporations and research labs, generative design is now becoming a practical solution for SMEs, thanks to:

- Improved accessible software such as Fusion 360 or nTop

- The emergence of local partners (Investissement Québec - CRIQ, ÉTS, Rio Tinto, etc.) capable of printing optimized metal parts

- Lower prototyping costs, especially for small or unique production runs

At the same time, performance, weight, and material reduction challenges are more relevant than ever—in transportation, sports equipment, and complex industrial products. For companies looking to reduce their footprint, boost competitiveness, or simplify production chains, now is the time.

Structured Adoption: Our Guidelines for Getting Started

Generative design is not a “magic button.” To become a real asset, it must be integrated into a structured process. Here are four key levers we use at Merkur to support its implementation:

1. Identify the Right Project

It all starts with the right entry point. A part that is low volume, expensive to machine, weight-sensitive, or hard to modify is often a great candidate.

Sometimes, it’s about replacing a broken part that’s difficult to reproduce. In other cases, it’s creating a one-time tool without investing in a traditional mold. The key is to start with a clear, concrete case where the ROI is visible and achievable.

2. Consider the Manufacturing Process

Some generative designs are only possible with 3D printing. For very complex parts, it’s often the only viable option. Metal 3D printing becomes essential.

But you can also guide the algorithm: specify that you want the part to be machined, forged, or molded. The tool adapts. You may lose some optimization, but you gain feasibility and speed. The key is knowing how to express your constraints.

3. Don’t Underestimate the Learning Curve

While user interfaces are improving, the design logic itself is shifting. You need to get used to new tools and learn to think differently: you’re no longer drawing shapes—you’re defining conditions and constraints.

This requires support. Targeted training, a pilot project with an expert, or partnerships with research centers—many paths are possible, as long as you plan for this skill-building phase.

4. Accept That the Best Solution May Not Be the One You Imagined

Generative design can disrupt habits. It may suggest shapes you’d never dare to draw. And that’s its power. The goal isn’t to validate your intuition—it’s to uncover new solutions that are often more efficient, more sustainable, and more relevant.

That takes openness. A willingness to test. And the ability to think outside the box.

Conclusion: A Step Toward Augmented Engineering

At Merkur, we believe generative design has a real role to play in the future of Quebec engineering—not by replacing people, but by freeing them from limitations. By giving them tools to design with more speed, precision, and insight—while maintaining control.

For SMEs, this is a concrete opportunity to innovate differently, design more efficiently, and tap into a technology lever that can truly make a difference.

Considering the leap? Have a part or project in mind? Our team can help you make the right decisions and build a structured approach that delivers results—contact us today!

Because sometimes, the best way to innovate is to rethink how we design.