Manufacturing industry

IMPLEMENTATION OF A NEW MANUFACTURING PLANT FOR ELECTRIC VEHICLES

The transport electrification sector is highly competitive, both in terms of the efficiency of solutions and the number of market players.

Merkur partnered with one of its clients to successfully complete a race against time. Speed, flexibility and key competencies were required to meet the challenge.

Merkur’s requirement

Our client, which manufactures various types of electric vehicles, needed Merkur to design and carry out an industrialization plan for a new zero-emission vehicle production plant.

Merkur partnered with the client on several levels :

- Established a multidisciplinary team of experts to plan and execute the project.

- Defined the project plan and needs analysis.

- Participated in the development of the manufacturing strategy and financing plan. (Budget, schedule, and square footage requirements).

- Developed processes, implementation of management tools and implementation of a document management plan.

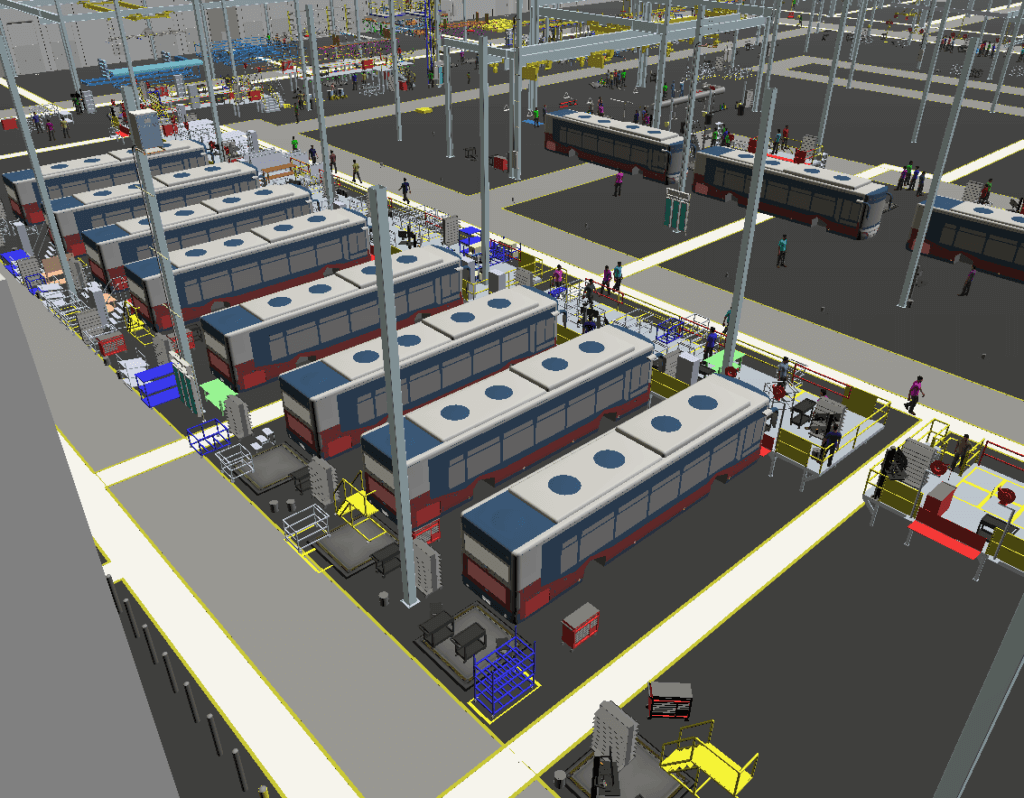

- Industrialization, technological optimization and overall layout of the plant and workstations.

- Detailed engineering management : building mechanics, equipment acquisition, logistics, work instructions, balancing and 3D operations simulation.

- Support for the implementation of the plant layout and the launch of production.

Results

- Adapted implementation and management approaches, in an agile mode, to align with client needs.

- Delivered an optimized high-level strategic plan.

- Delivered detailed layouts, production line balancing and related work instructions.

- Facilitated procurement of all equipment required, includingassembly station material, handling systems, and technological test and measurement systems.

- Implementation of an information transfer process : Station layout, technical documents, project management phased process, creation of reporting tools.

- Simulation of critical operations using Flex Sim.

Main Challenges Overcome by Merkur

- Met a tight schedule, driven by the competetive nature of the electric vehicle industry, to meet our client’s Time to Market needs.

-

Adapting to evolving project requirements driven by changing market demands, necessitating work in an agile mode.

Resequencing of milestones and restructure of the project to allow our client to align to their market needs. - Large-scale project coordination of a multi-site and multidisciplinary team, including management of product engineering, procurement and industrial engineering resources located in three different locations (Boisbriand, Sherbrooke, Chicago).

- Design and creation of structures and processes that allowed our client to manage its first major project.

- Transformation of existing and Implementation of new manufacturing strategies designed to help our customer reach their target productionrates.

Additional Benefits of this Collaboration with Merkur

- Client was able to fill labor gaps with qualified resources provided by Merkur.

- Faster project implementation and Time to Market by utilizing Merkur’s team of external consultants.

- Leveraging of Merkur’s expertise to provide solutions in paint application, quality and procurement.

- Education and knowledge tranfer to our client’s new hires in key roles across the organization.

The Merkur Method :

A Partnership of Trust that makes a Difference.

Merkur offers you a winning solution by adapting to your challenge.We have the team, the tools and the knowledge to contribute to your success

and can supply specialized talent to fill key roles that you may not have in-house.