Industrie manufacturière

Design of Tooling to Support the Recreational Boat Production Line

The recreational boat industry is a highly competitive market where product customization is essential. The partnership between Merkur and its customer has enabled the latter to implement the solutions best suited to its needs.

In the context of highly diversified products with a multitude of options, developing a unit flow and assembly line with short lead times is essential to maintain market leadership.

Merkur’s team takes pride in helping its customer launch new products every year.

Merkur’s Mandate

Merkur accompanied its client in the production of a new range of recreational boats: Aluminium Pontoons and Boats.

In helping to understand and analyze its production line, Merkur was involved in the design of jigs. The purpose of these jigs was to position and hold the parts together during the assembly stages.

Objectives

- Ensure the increase in speed with the help of the designed tooling.

- Design a tooling with a very good capability: repeatable and reproducible in order to guarantee the quality of production.

- Validate assembly sequences: from manufacturing to installation, Merkur's objective was to offer collaborative thinking based on its global vision of the various assembly stations.

- Promote ergonomics and safety at workstations.

- Determine if the tooling requires some form of automation and design it when necessary.

Results

50

different tools designed

15h

to

500h

of design time spent on a tooling

4

designers on the project

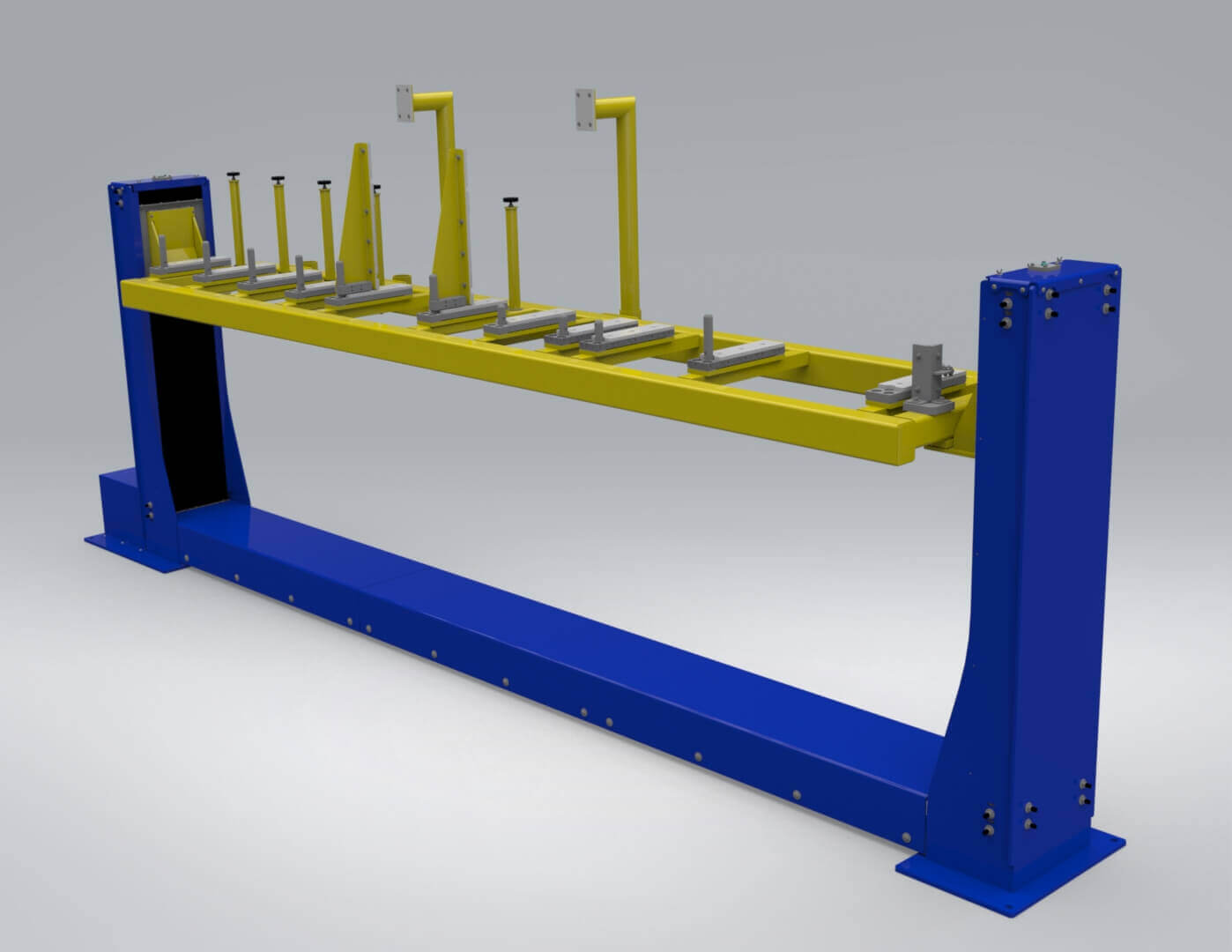

Mobile assembly fixture with pneumatic option.

Under assembly boat structure. Quick positioning of the main parts. The fixture is used for riveting and mechanical assembly operations and for the installation of aesthetic components.

Production fixture with reversal option. Boat cabinet sub-assembly. 360° handling for easy access by the installer. The fixture is used for rivet and mechanical assembly operations, installation of aesthetic components and electrical installation.

Main challenges overcome by Merkur

- Adapt to the very tight deadlines imposed by this competitive market in a Time to Market context.

- Integrate the latest developments in product design simultaneously with the design of the assembly equipment by being adaptable and agile.

- Take into account the dimensions and weight of bulky parts. Merkur has been able to propose working methods that considers this constraint: The need to turn the parts to work them well. Respect the ergonomics of workstations with bulky parts.

Merkur's expertise for this project

- Deploy a collaborative and tailored approach: Evaluation and understanding of customer needs by exchanging with the engineering teams. Participate in the elaboration of specifications and follow their evolution.

- Propose an adaptable solution and a flexible team with variable capacity.

- Offer expertise in manufacturing and more specifically in tooling with this type of pace. Merkur experts have the knowledge of tooling for drilling, gluing, riveting, welding, etc.

- Guide the client by proposing design evolutions when it is relevant by performing simultaneous engineering.

La méthode Merkur :

Un partenariat de confiance qui fait la différence.

Merkur vous propose une solution gagnante en s’adaptant à votre défi. Nous possédons l’équipe, les outils et les connaissances pour contribuer à votre réussite.

Offrez-vous des talents spécialisés afin de combler les compétences clés nécessaires au projet que vous ne possédez pas en interne