Industrie manufacturière

Transformation numérique facilitée grâce à la solution de connectivité SYNKRO

Notre client, un leader mondial en procédés chimiques, souhaitait éliminer tout papier de son plancher de production. Pour ce faire, l’implantation de SYNKRO était de mise afin d’automatiser certains processus et ainsi éviter la retranscription manuelle entre les différents systèmes mis en place.

Mandat de l’équipe

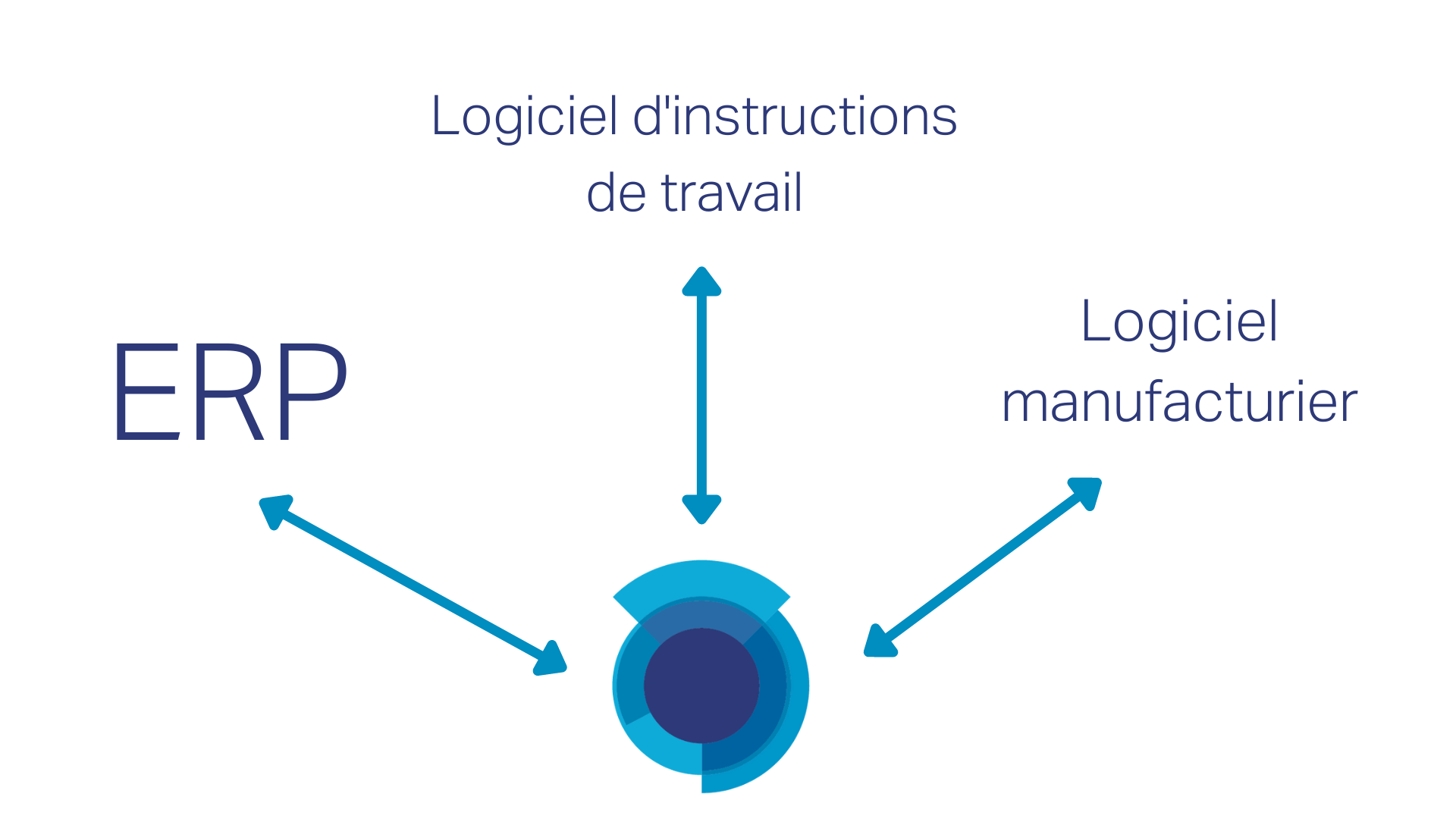

En possédant déjà un ERP (ProcessPro), un logiciel d’acquisition de données manufacturières (CapStone) et un logiciel d’instructions de travail (VKS), le mandat de l’équipe Synkro consistait à construire les ponts entre les différents systèmes afin d’acheminer les requêtes aux bons systèmes. Par exemple, au lieu d’entrer manuellement plus d’une centaine de bons de travail à faire dans le logiciel à cet effet, Synkro se charge d’acheminer la requête de l’ERP jusqu’au logiciel d’instructions de travail afin d’éliminer les risques d’erreurs reliés à la retranscription manuelle. Au cours des opérations, Synkro se charge également de lire certains capteurs machines, valider les résultats de laboratoires, initier les consommations matérielles (ayant au préalable, en temps réel, vérifié les inventaires), le tout avec un minimum d’intervention humaine. Ces ponts ont permis de changer complètement la réalité de l’opérateur qui devait effectuer des allers-retours constants entre les différentes applications concernées.

Bénéfices de l’implantation de Synkro :

- Accélération du processus des opérations

Sans Synkro, le maintien du même niveau de détail des requêtes n’aurait pas été possible et aurait ajouté un surplus considérable à l’opérateur. En simplifiant l’acheminement des requêtes entre les systèmes, ce processus en est alors accéléré.

- Augmentation de la qualité du travail

En éliminant la retranscription manuelle des procédures, bons de travail et autres informations, celles-ci sont suivies à la lettre et permettent une qualité du travail supérieure, les erreurs manuelles étant inexistantes.

- Efficacité accrue

En supprimant la saisie manuelle et les papiers du plancher de production, la formation des ressources humaines est simplifiée et plus efficace, ce qui représente un gain énorme en contexte de pénurie de main-d’œuvre.