Our approach to Industrial Projets Management

01 /04

We validate the relevance, feasibility, and priority of the project. This phase clarifies needs, reduces uncertainty, and establishes a solid roadmap.

- Define objectives

- Analyze opportunities

- Compare best practices

- Estimate the budget

- Identify initial risks

- Structure the roadmap

02 /04

We move from analysis to action by formally launching the project, engaging stakeholders, and validating technical choices to support structured planning.

- Define the manufacturing strategy

- Formalize the project charter

- Map stakeholders

- Establish a high-level schedule

03 /04

Rigorous, proactive management ensures coordination, cost and schedule tracking, and compliant delivery of deliverables, while adapting to on-the-ground realities.

- Deploy the management plan

- Mobilize the project team

- Coordinate engineering and integration

- Drive progress and decision-making

- Manage strategic procurement

- Control deliverable quality

04 /04

We ensure the handover to operations, ramp up production, and adjust processes, while strengthening operational efficiency over the long term.

- Ensure the handover to operations

- Support production start-up

- Resolve on-site issues

- Optimize processes and performance

- Structure continuous improvement

Our services at the core of the integrated solution

Designed strategically, our services ensure smooth, consistent, high-performing management of your industrial projects. Our integrated solution reduces risk, accelerates delivery, and maximizes results at every stage.

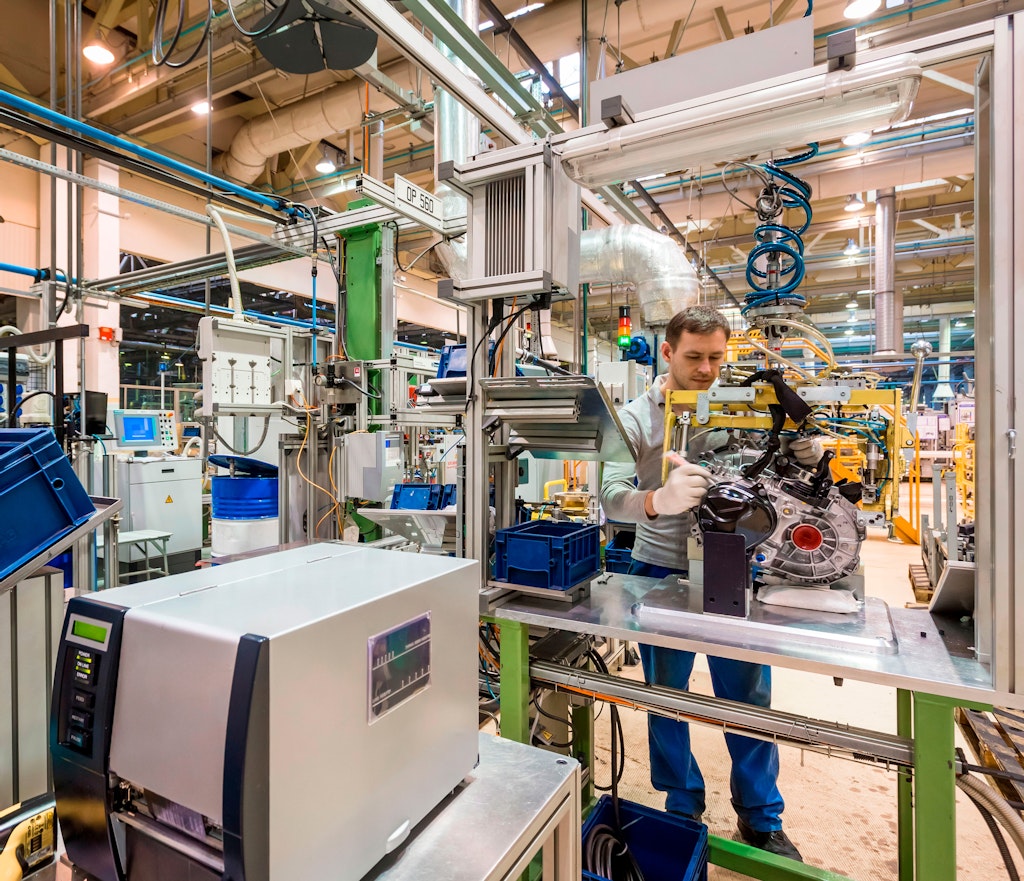

Manufacturing Project Management

From strategy to operations: governance, risk, quality, EHS and performance for successful, measurable startups.

Expansion and implementation of facilities

Your partner to plan, coordinate and deliver plant expansions or greenfield factories: project management, facility layout, commissioning and startup support.

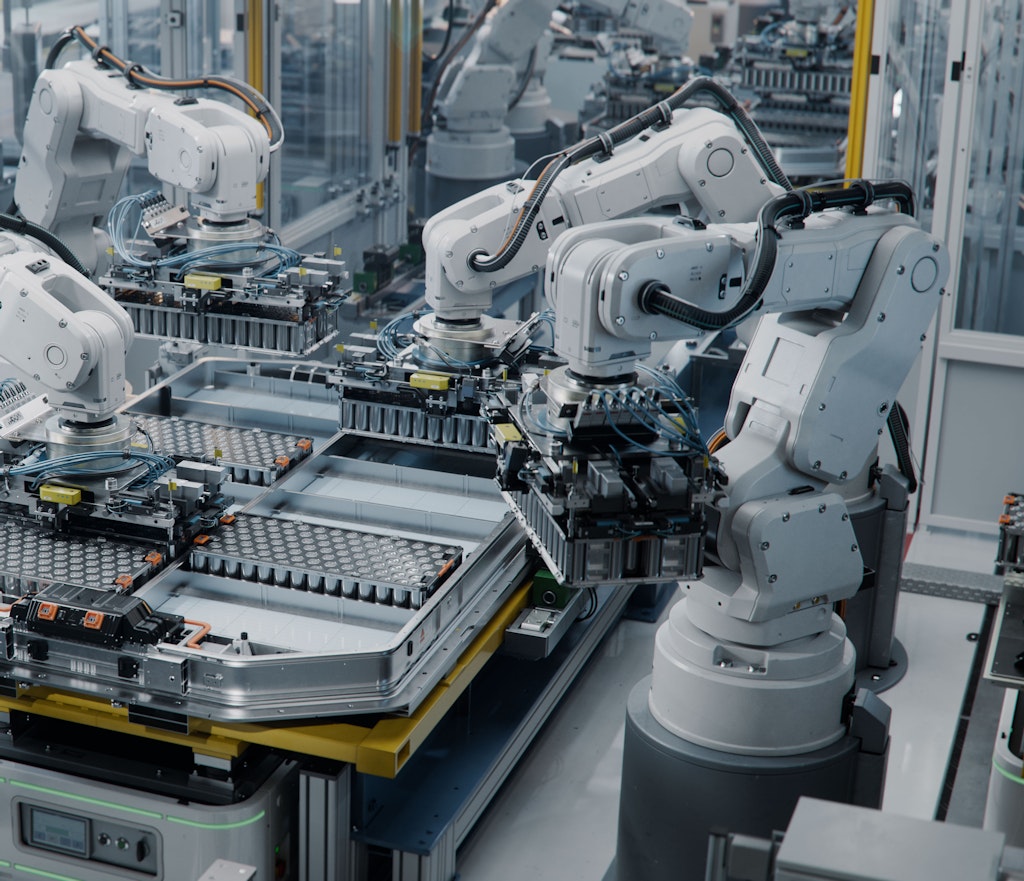

Industrial Automation and Robotics

Discover how Merkur designs and delivers automation and robotics solutions to optimize your processes and accelerate industrial transformation.

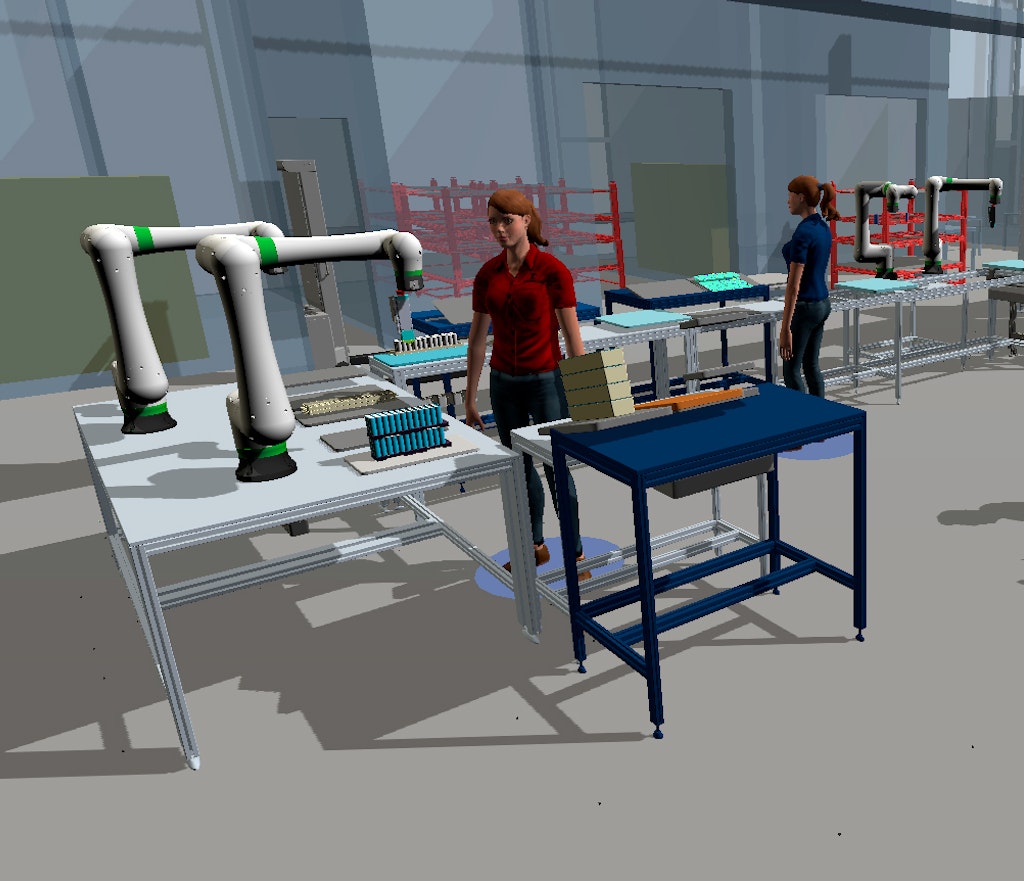

Manufacturing Simulation

Before automating, reconfiguring, or expanding, simulate your operations in 4D. Visualize impacts, eliminate bottlenecks, and maximize ROI.

Infrastructure and Building Services

From needs assessment to testing and commissioning: Merkur coordinates electrical power, compressed air, HVAC, process water and fire protection for seamless integration into plant operations.

Tooling and Equipment Design

From requirements to commissioning: Merkur designs and integrates industrial tooling and equipment (mechanical, hydraulic, pneumatic, electrical, automation) to make operations safer and more productive.

Projects

Automation Strategy for a New Production Line

Manufacturing

Merkur worked with its client, an electronic components manufacturer, to implement an automation strategy for its new production line by deploying an operations simulation using FlexSim®.

Optimisation of a new plant’s secondary operation lines

Transportation

A transportation products manufacturer with a global presence wanted to start manufacturing large composite parts in a new plant.

Articles

4D at your Expansion Projects’ Service

You’re ready to expand or redesign your plant to support future growth, but you’re wondering how to go about it efficiently? Would you like to mobilize your teams around this strategic project for your company? Are you wondering about the right tools to support your communication during this change with tools that confirm your production strategy?

Simultaneous Engineering : Decide Quickly, Deliver Well - Integrate Product, Process, and Infrastructure from the Start

What if your next infrastructure project had to move forward… without all the answers in hand?

H55 Calls on Merkur for New Plant in Quebec

Discover how innovation and electrification are redefining aviation through the strategic collaboration between H55 and Merkur.