Automation Strategy for a New Production Line

- Client

- Confidential

- Sector

- Manufacturing

- Expertise

- Industrial Automation and Robotics

- Manufacturing Simulation

CONTEXT

CHALLENGES

ASSIGNMENT

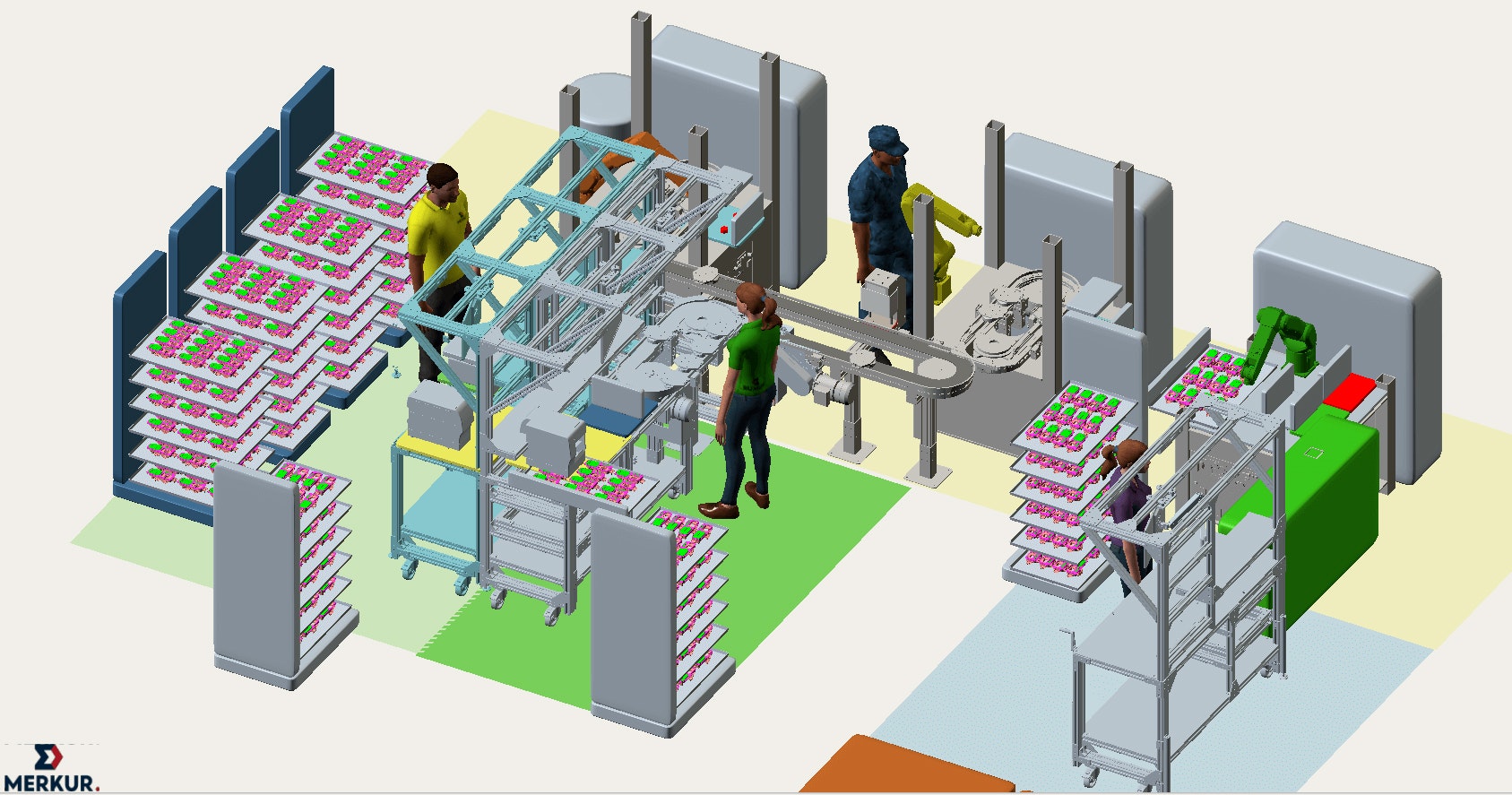

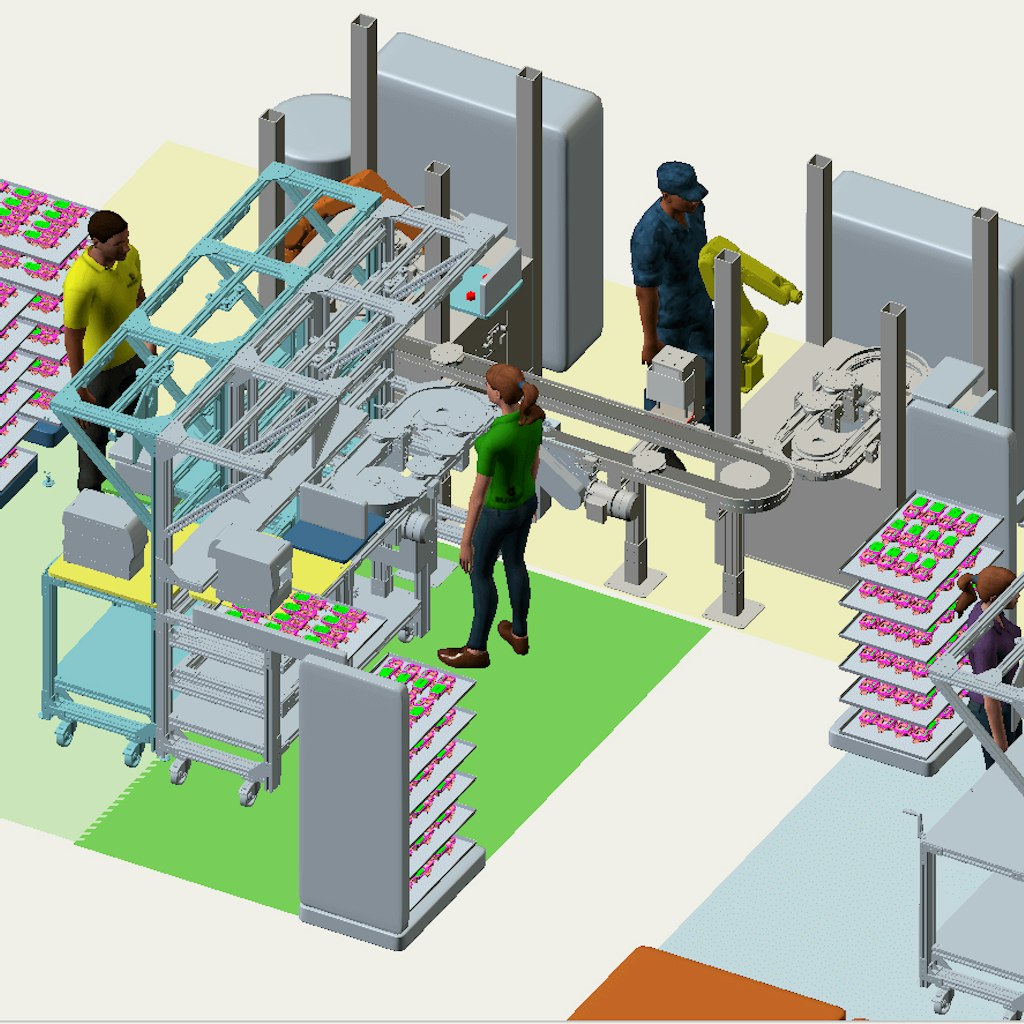

Merkur supported its client in implementing an automation strategy for their new production line.

The goal was to automate manual operations, reduce movements, and implement robotic processes through operations simulation.

RESULTS

Develop a flexible production line, from raw material inspection to product canning

OBJECTIVE AND ACTIONS

Define line automation strategy

Define line automation strategy

- Reduce tooling costs by using existing processes and equipment

- Target the production line processes where automation is most cost-effective

- Improve the efficiency and ergonomics of workstations, material flows, and minimize travel

- Integrate 4 new products

- Level out production peaks for different products on an annual basis: seasonally variable production

TOOLS AND TECHNIQUES

Current process mapping

Target and analyze irritants and opportunities

Study of current line to reduce waste

Analysis of production line times: Gathering information to simulate a line

Simulate and develop 3 scenarios on FlexSim (current and future)

Merkur est en mesure de simuler des îlots de production optimaux et performants grâce à notre outil FlexSim®. Le flux et les opérations sont optimisés afin de rencontrer les objectifs d’espace et de temps de cycle de notre client.

Kévin Martinez

Robotics Project Manager - Manufacturing Project

Merkur

DISCOVER OUR PROJECTS

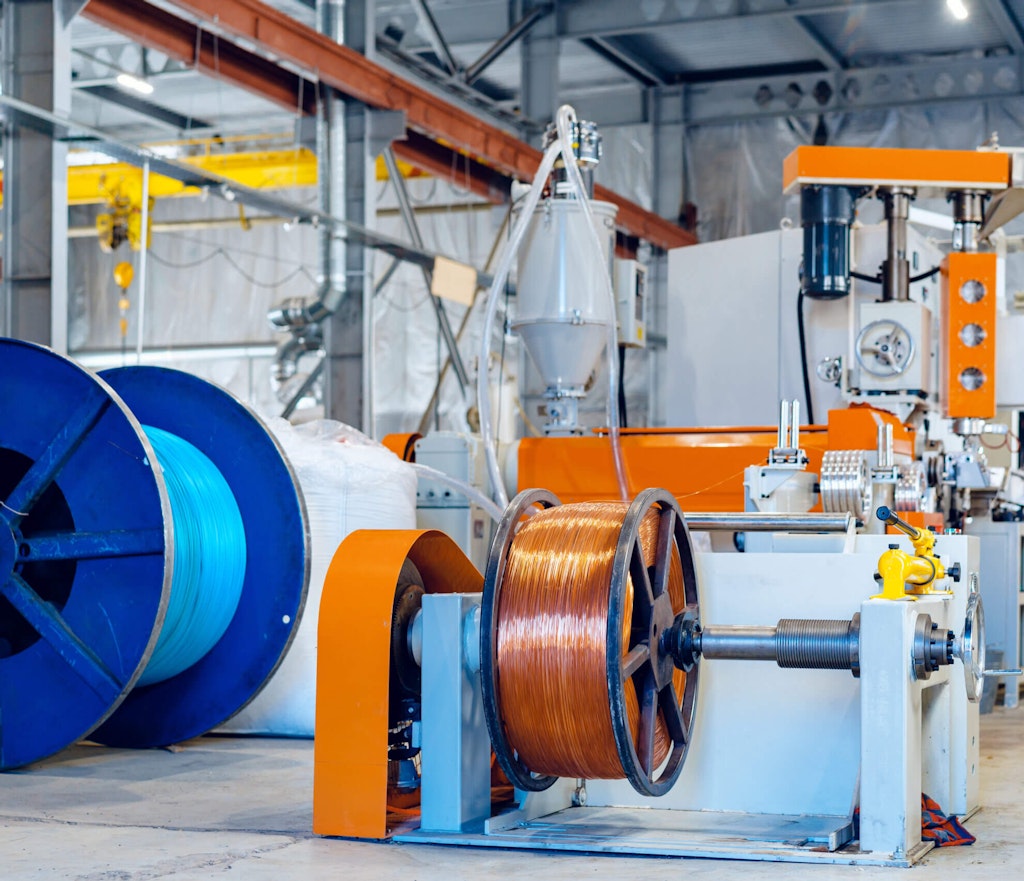

Pull Flow Adoption to Streamline Production and Reduce Work in Progress

Manufacturing

Specializing in the manufacturing of electrical cables coated with high-performance materials, our client operated under a push flow production model, based on make-to-stock manufacturing. The company initiated a shift to a pull flow system to reduce work-in-progress, streamline flows, and increase organizational agility. Merkur took over and successfully implemented this transformation.

Support for pontoon boat design and manufacturing

Manufacturing

Our customer needed to design and manufacture a pontoon boat for a sister company in the U.S. on their own premises, while retaining the company’s DNA. Our customer lacked engineering and project management capabilities.

Warehouse Consolidation and Design of a Multisite Logistics Network

Manufacturing

Our client in the powersports industry aimed to introduce a new range of modular products and double its production.