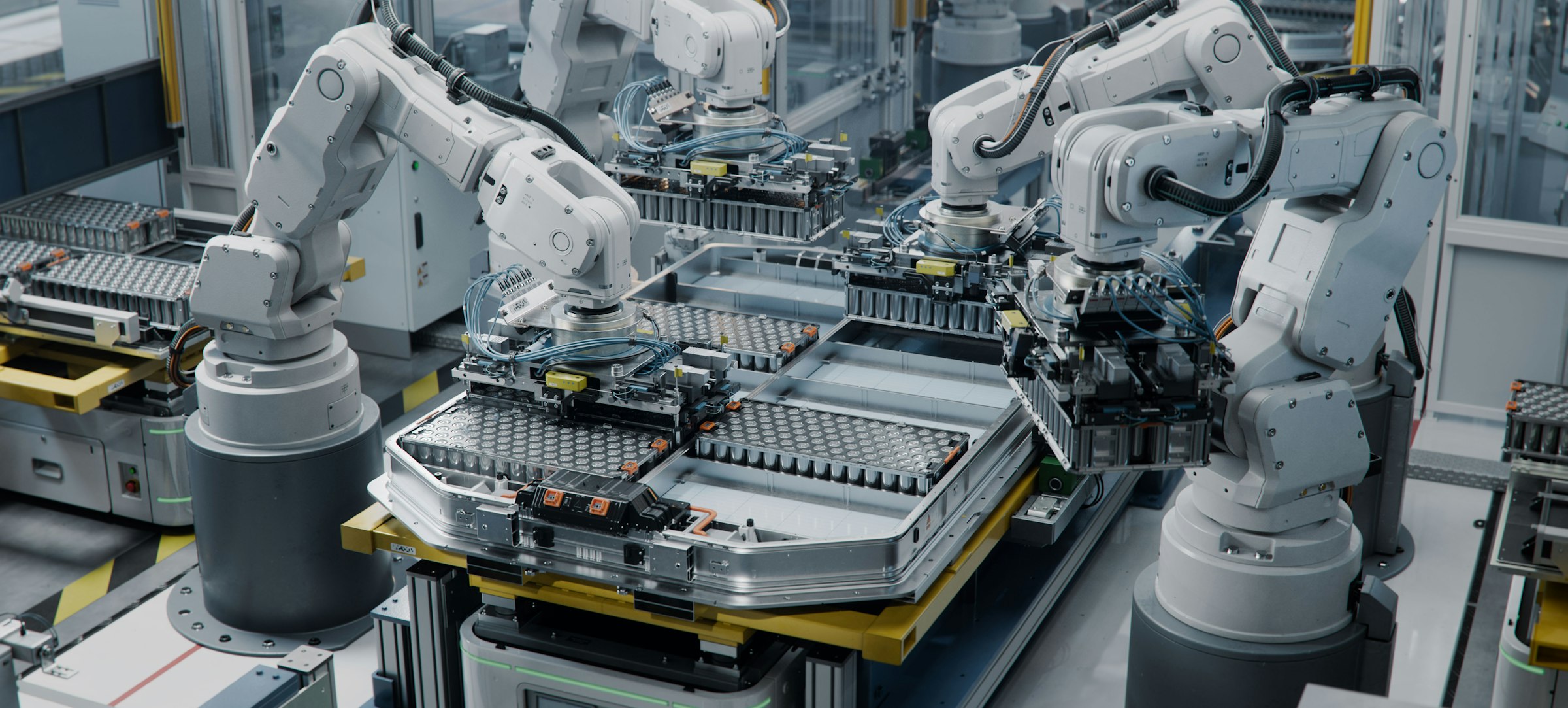

Automation and Robotics

Boost your industrial performance with automation and robotics solutions tailored to your challenges. Merkur supports you at every stage of your projects, regardless of your industry or maturity level, with a flexible, hands-on, results-driven approach.

OUR EXPERTISE

Automation: More Than Robots, a Strategic Lever for Competitiveness

Automation: More Than Robots, a Strategic Lever for Competitiveness

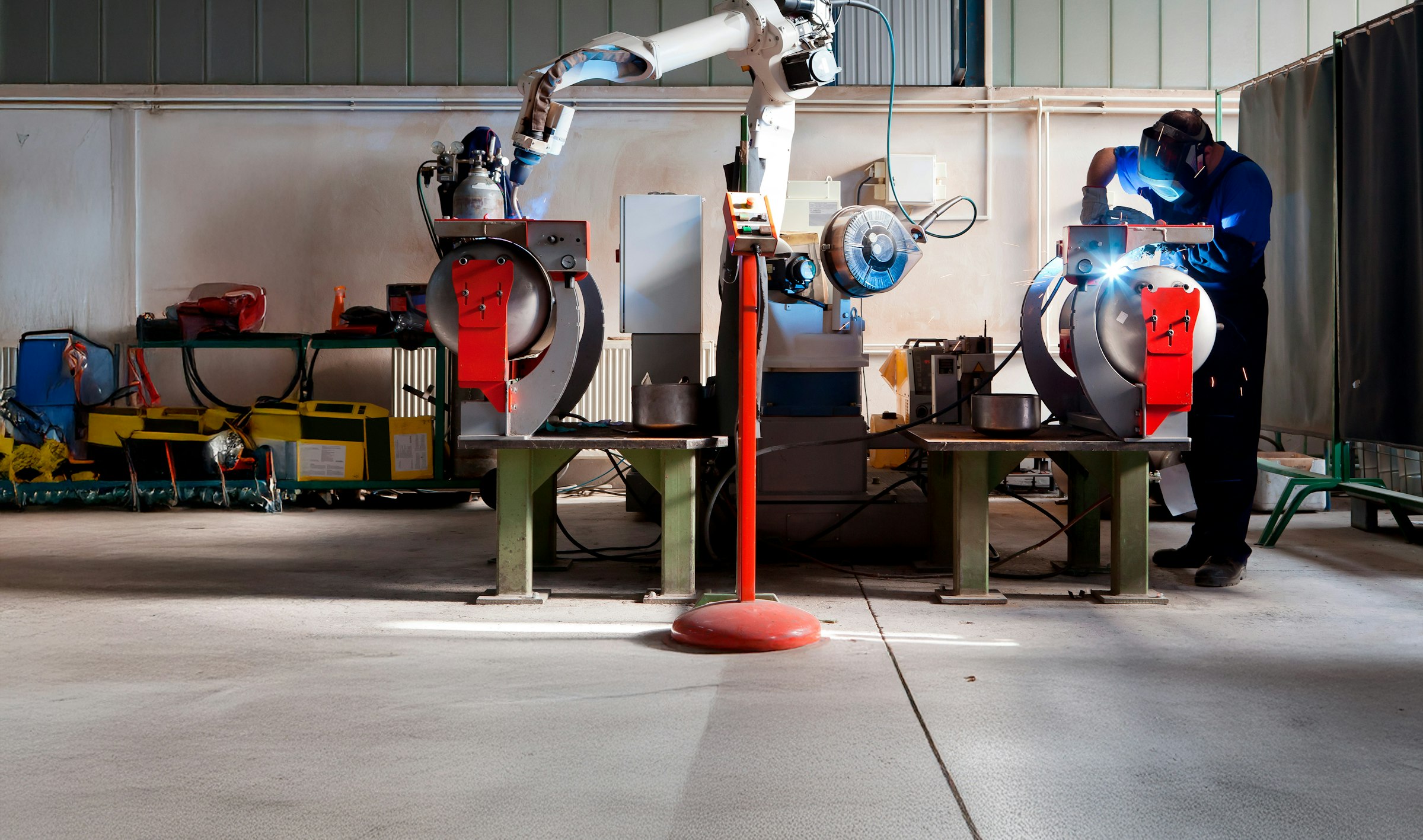

Automation is a driver of sustainable performance when approached strategically. By freeing your teams from repetitive tasks and focusing on human value creation, you improve productivity, quality, and organizational engagement.

Merkur supports you in the integration of robotics, automation, and process control solutions through a tailored approach aligned with your business objectives. Our experts combine strategic vision, technical expertise, and hands-on experience to accelerate your digital transformation and maximize operational performance.

- Invest in the right projects

- Connect your machines

- Automate operations

- Automate processes

- Modernize your equipment

- Improve quality

- Reduce reliance on labor

- Innovate and transform your processes

Tools

SCADA

Programmable Logic Controllers (PLC)

Robots

Artificial Intelligence

Cybersecurity

Synkro® / Dashboards (KPI)

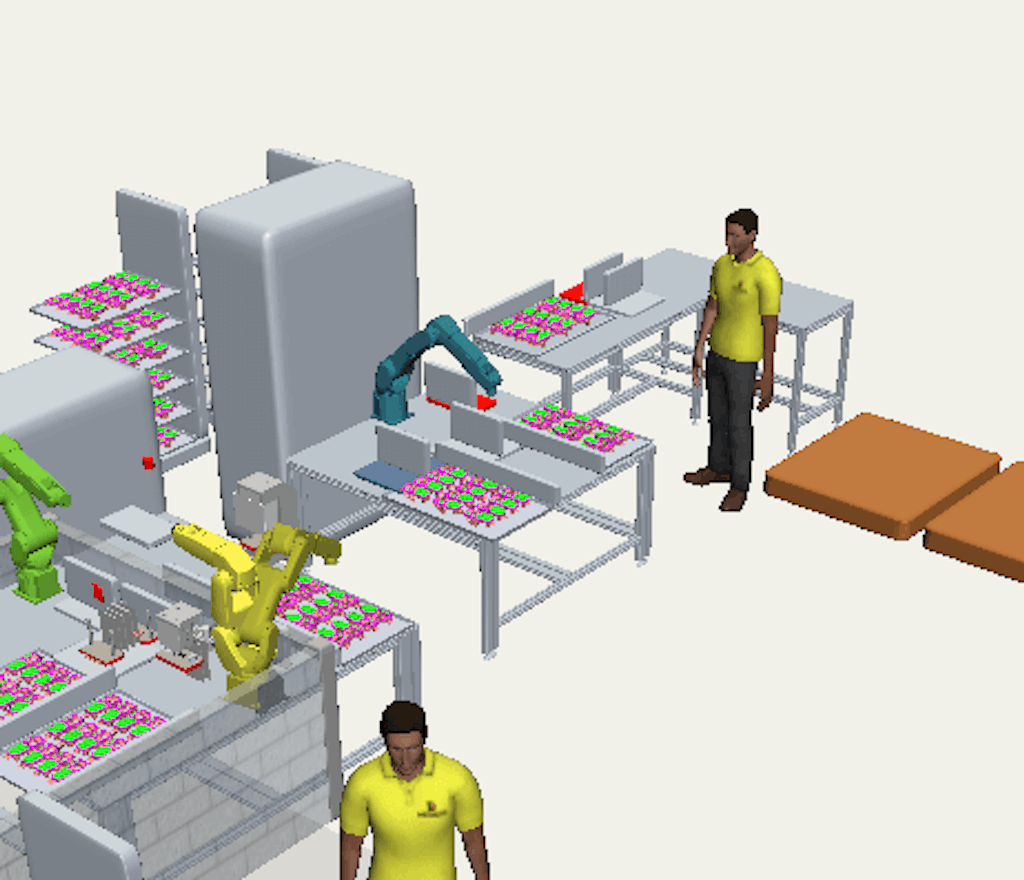

Simulation / Flexsim

Your projects require more than technical expertise. They demand a partner who can deliver. With our integrated solution, entrust us with the management and execution of your project, from planning to commissioning, for a controlled implementation and tangible results.

Innovative Automation Strategies

Transform your functional and regulatory requirements into robust, modular, and industrial-ready concepts, designed for validation and production.

Our Team at the Heart of Engineering

Our designers and engineers analyze your needs and constraints, conduct targeted technology scouting, and recommend the most relevant solutions for your operational reality.

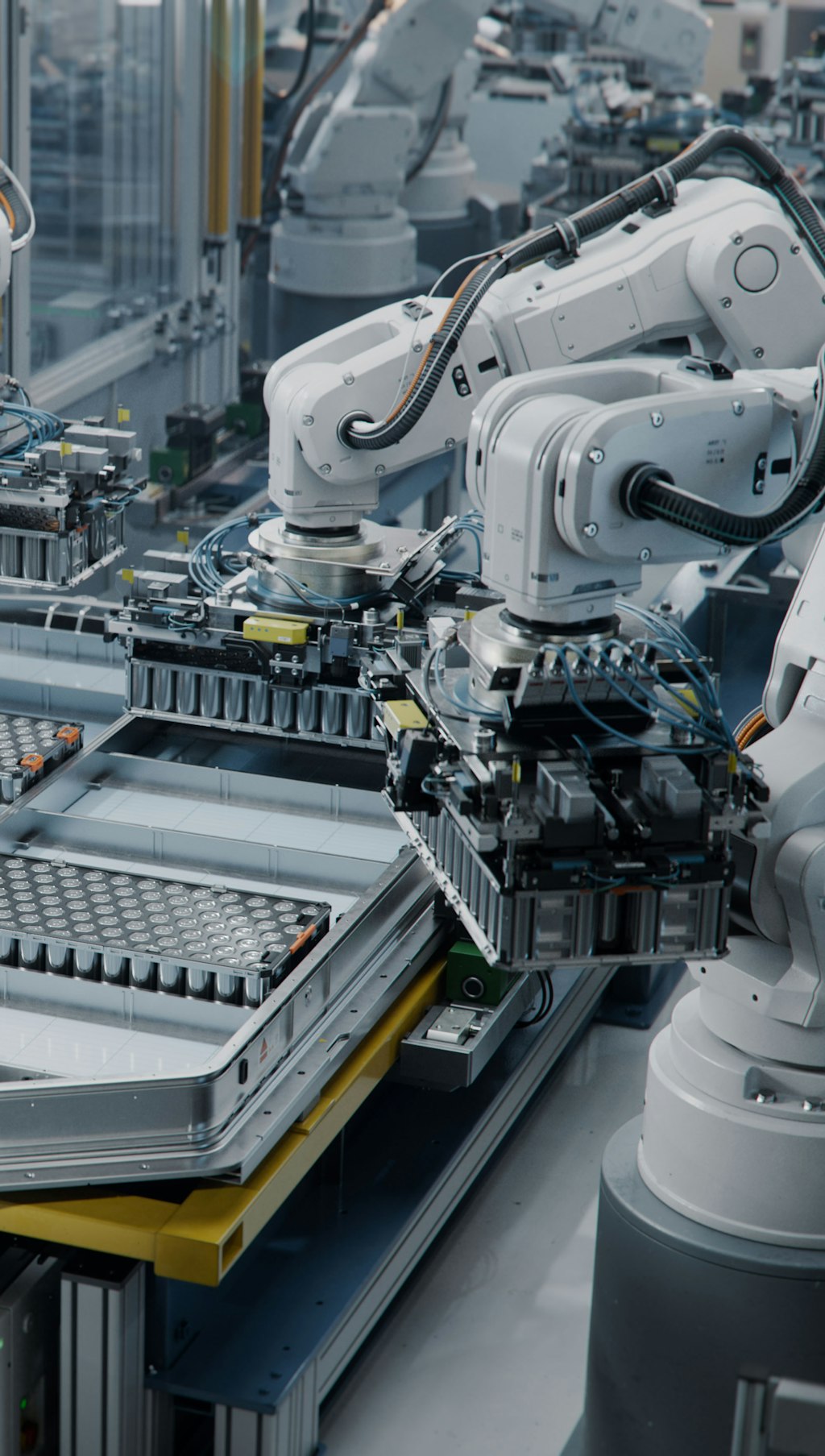

A Comprehensive Approach to Automating Manufacturing Processes

With Merkur, automation becomes a strategic lever. Combine flow optimization, simulation, and tailored solutions to transform your processes into intelligent, flexible, and high-performance systems.

PROJECTS

Automation Strategy for a New Production Line

Manufacturing

Merkur worked with its client, an electronic components manufacturer, to implement an automation strategy for its new production line by deploying an operations simulation using FlexSim®.

Development of Bus Handling Equipment

Transportation

One of our customers, a manufacturer of passenger buses and motor homes, decided to replace the ferries in its passenger bus assembly plant.

ARTICLES

How Merkur Maximizes the Value of Your Investments in Automation Projects

Are you considering an automation project but lack the expertise or resources to take action?

The Essential Benefits of Robotic Simulation for your Project

H55 Calls on Merkur for New Plant in Quebec

Discover how innovation and electrification are redefining aviation through the strategic collaboration between H55 and Merkur.