A successful digital transition for Metalus’s new smart factory

- Client

- Metalus

- Sector

- Manufacturing

- Expertise

- Operational Systems Management

- Digital Transformation

CONTEXT

CHALLENGES

ASSIGNMENT

Digitizing operations: a first step toward Factory 4.0

Merkur supported Metalus in digitizing its operations to make the plant more efficient and connected.

RESULTS

30 %

reduction in errors

OBJECTIVE AND ACTIONS

With the help of Merkur’s experts and SYNKRO software, Metalus successfully made the transition to a smart factory.

With the help of Merkur’s experts and SYNKRO software, Metalus successfully made the transition to a smart factory.

In order to successfully digitize Metalus’s work orders, Merkur structured the processes and implemented digital solutions to connect operations.

TOOLS AND TECHNIQUES

Overhauled the company’s main business processes

Implemented the SYNKRO platform and VKS software

Connected the factory equipment

Implemented real-time tracking of performance indicators

The digitization of work orders did more than just eliminate paper from the company’s daily operations. Thanks to Merkur’s multidisciplinary approach, the switch to digital also gave company managers real-time access to production data. This invaluable information has become an indispensable tool that enables management to take rapid action fast when human intervention is required.

Merkur

DISCOVER OUR PROJECTS

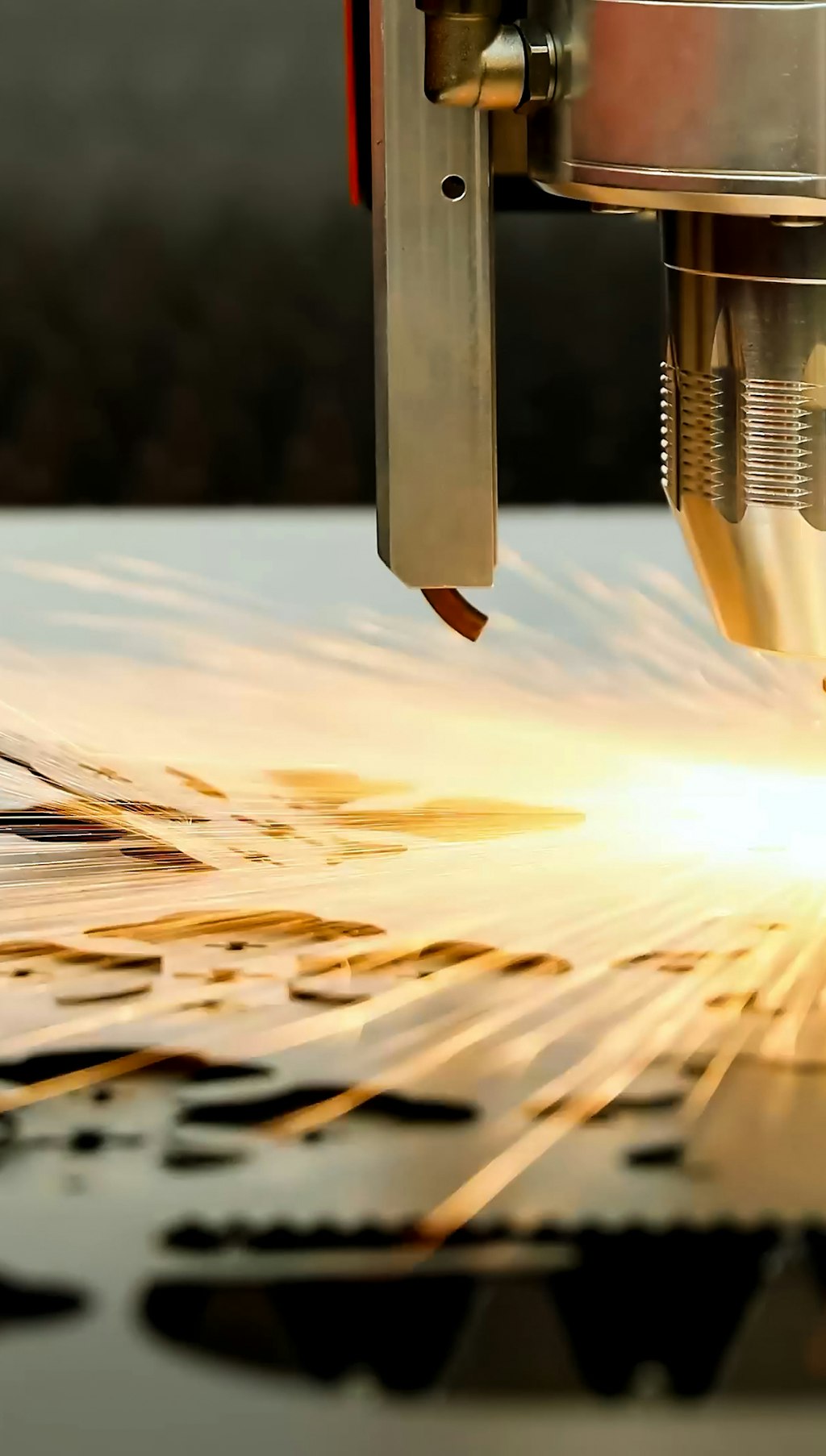

Matritech: A Large-Scale 4.0 Turnaround

Manufacturing

Matritech is a manufacturer of metal components with varying production volumes. Operating as a one-stop shop, the company brings together multiple manufacturing processes. Merkur is supporting Matritech’s team through its major Industry 4.0 transformation.

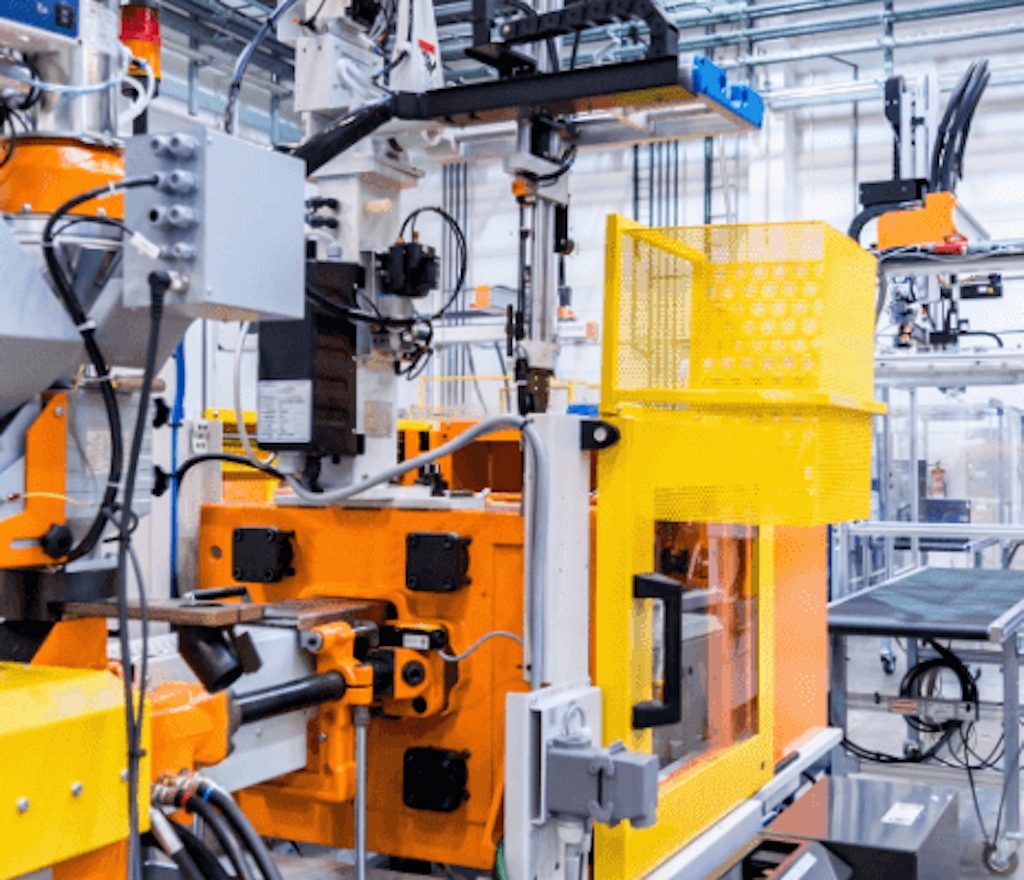

Digital transformation made easy with the SYNKRO® connectivity solution

Manufacturing

Our client, a world leader in chemical processes, wanted to eliminate paper from their production floor. They decided to implement SYNKRO in order to automate certain processes, therefore avoiding having to manually transcribe information for various systems in place.

Standardizing Production Through Digital Transformation

Manufacturing

Our client, Canam Group, specializes in the design and manufacture of metal components for the construction industry in North America. With the acquisition of three plants, Canam Group wanted to find a solution to remotely monitor the status of its machinery in order to implement production improvements.